10 ton overhead crane for sale to Ethiopia. overhead crane installation service for our Ethiopia customer. 6 sets 10 ton Double Girder Overhead Crane installation in Ethiopia pipe-making plant. Learn 10 ton overhead crane specification and transaction process to get the crane information that you need.

Since 2016, Ethiopia economy has been developing rapidly, the government support lots industries to establish their new workshops, so Mr Ashenafi built three new warehouses for pipe making. We Dongqi Group contacted Mr Ashenafi from the beginning of January, 2016, after learning the crane needs of pipe-making warehouse, our sales director Mr Oscar was responsible for giving below solutions:

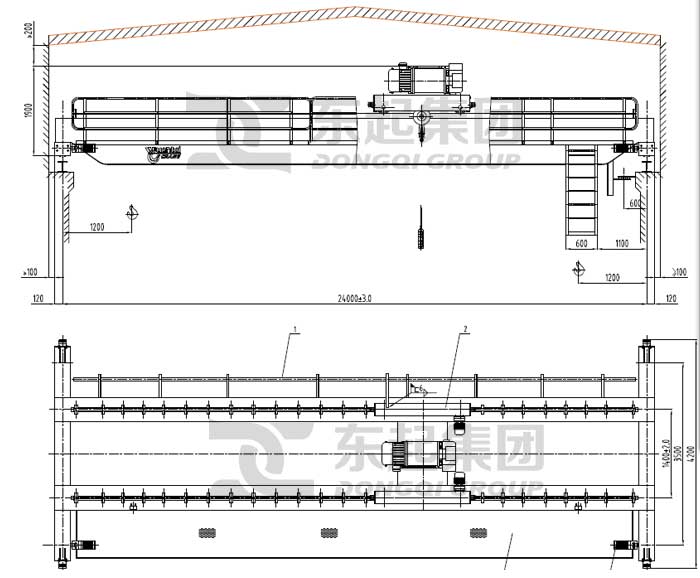

10 Ton Overhead Crane Drawing

Mr Ashenafi was very satisfied with above crane solution, after a period of communication about some crane technical question, then sign the contract at the end of 2016 and totally amount is US DOLLARS 143,000.00.

On 8th May, Our technical team visited our Ethiopia customer Pipe-Making Plant, for installation and commission of 6 sets 10 ton double girder overhead crane, which is shipped and arrived customer’s plant last year, on that day Mr Ashenafi arrange people to pick Mr Chen up at the airport.

On the second day after arrival, Mr Wei request to go to warehouse to check all the overhead crane girders, boxes, electrics boxes, beams and rails and other crane spare parts which could ensure all crane parts are ready, then Mr Chen had a meeting with Mr Ashenafi and his team, Mr Wei told them to prepare related overhead crane installation tools, such as mobile crane, welding machine, screwdriver, forklift, lever etc, and how many people it will need to ensure the overhead crane installation process operate smoothly.

The 6 sets overhead crane will be used in three warehouse:

Until 31th May, 5 sets overhead crane installation have been finished well, the other set will need extra 3 days, after that, Mr Chen will arrange the heavy load to commission the crane and adjust the working stability. After all installation and commission finished, he will teach the workers how to operate and maintain these overhead cranes, everything goes smoothly during the overhead crane installation, commissioning and inspection.

Our team has talked with Mr Ashenafi after all overhead crane installation finished, he agreed other customers to visit his plant to see our overhead cranes, so all Ethiopia customers and friends, if you have any cranes projects or want to know more of our company and our cranes, welcome to contact us!

Hoisting machinery is a special type of equipment and has a high degree of danger. Therefore, in the installation of cranes, safety work is particularly important. Special attention must be paid to the following aspects:

The overhead crane needs to be welded during the installation. The quality of the welding directly affects the performance of the crane. If there is a defect in the welding, it may cause the welding place to be weak, prone to cracking, reduce the working strength of the welding part, and in serious cases it will cause a safety accident. Therefore, attention should be paid to the welding defects of cranes. Several common welding defects during crane installation are as follows:

In the welding process, single-sided fusion welding is performed. Due to unreasonable welding processes, such as improper groove processing, unreasonable selection of current welding speed, etc., a large amount of weld metal is transmitted through the back surface, resulting in the collapse of the front surface of the weld seam. The back of the seam appears raised and this side is collapsed. After the collapse occurs, the strength of the weld will decrease and the stress will be too concentrated.

During welding, due to excessive heat input, such as wire feed too fast, the torch running too slowly, etc., the molten metal flows out from the back of the groove, forming perforations in the weld, which is burned through. Burn-through is a common welding defect, especially when welding some thin plates. Welds that have burned through will not be guaranteed for continuity and compactness and should be repaired as soon as possible.

Weld beading refer to the fact that during welding, due to improper operation, such as excessive current and slow welding speed, the molten metal flows to the base metal outside the weld and does not melt. The deposited metal formed on the edge of the weld and the base metal things. The inside of the weld has no penetration, affecting the welding quality.

When performing arc welding, due to arc extinguishing, arcing or arcing is not reasonable and other reasons lead to low enthalpy at the end of the weld bead. The occurrence of craters will reduce the strength at the end of the weld and reduce the weld cross-section.

Welding feet and welding throats are of reasonable size and have not reached the specifications and specifications specified in the sample drawings. If the dimension is too small, the strength of the weld seam will be reduced. If the dimension is too large, the deformation will increase.

10 ton overhead crane for sale Ethiopia case for your reference. 10 ton overhead crane installation steps make you learn overhead crane more. Crane installation precautions and welding defects needs to pay special attention.