The crane rail is a crane running route laid by rails, which ensures that the crane runs along the prescribed route and transmits the wheel pressure to the foundation. Crane rail can be divided into light rail type (P) and heavy rail type (QU). Small tonnage, medium tonnage crane rail uses P-type railroad rail, large tonnage gantry crane rail uses QU type crane special rail or square rail.

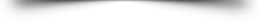

Crane rail have special rail, railway track, square rail and p-type rail, square rail wear to the wheel is relatively large, and now rarely used. Most of the crane trolley uses P type crane rail. Crane track selection as the following table:

Crane rail classification and selection

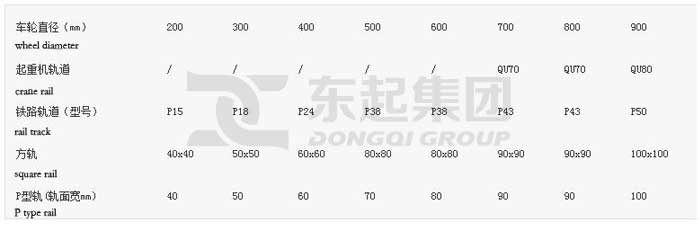

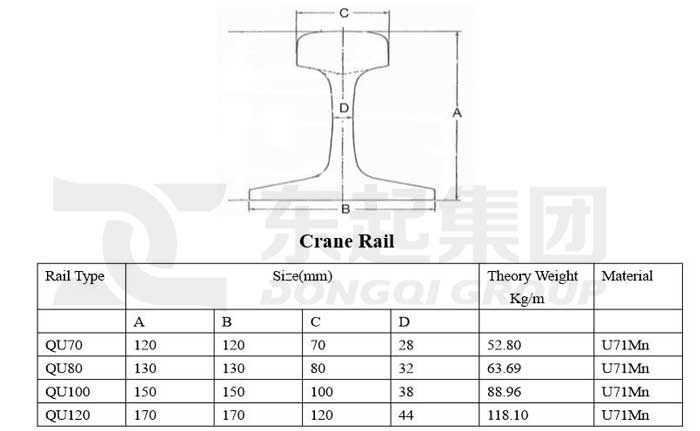

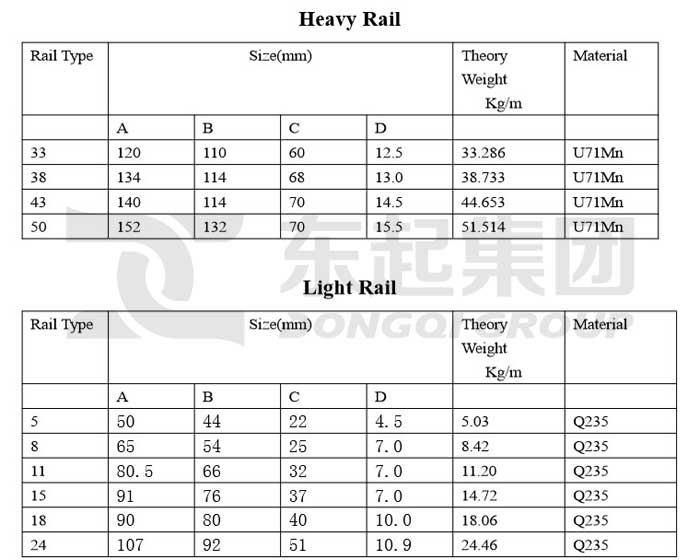

QU type crane rail Specification

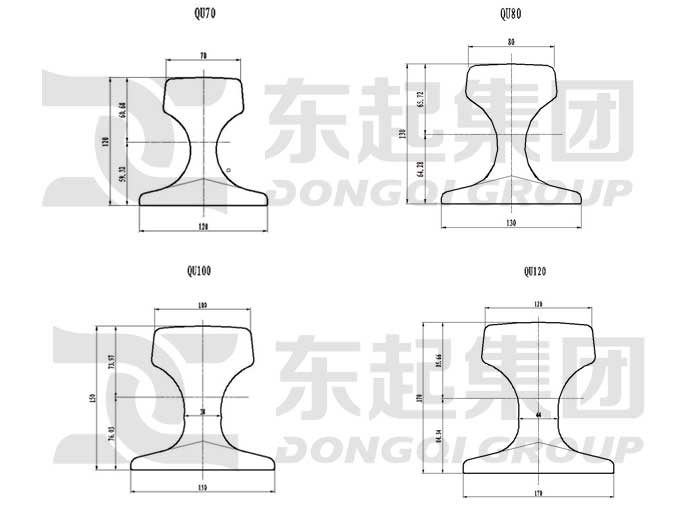

P type crane rail Specification

Crane rail specification

The crane's trolley track must be fixed on the travel beam, the trolley track fixed on the main beam. When the crane is in operation, the crane track cannot move laterally and longitudinally, and the crane track must be easy to adjust.

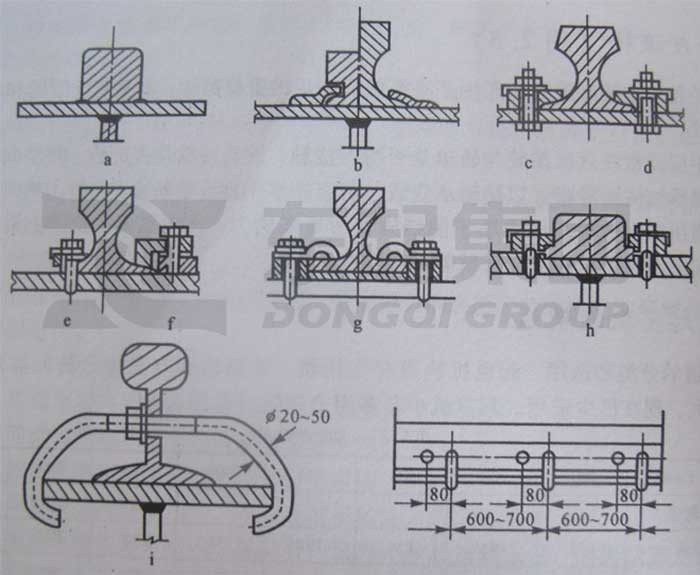

The fixed models of crane rails on the main beam are as follows:

Crane rail fixation

As shown in picture, including: crane track connection model

Check the rail, bolt, plywood before the crane rail installation, and replace it immediately if there are any cracks or irregularities. For the steel rail surface and side that are allowed to be repaired, the wear defect should not exceed 3mm steel rail, repair it before using.

Crane rail supplier for overhead crane and gantry crane. Dongqi Group supplies you crane rail and crane rail installation service. Contact us to get cranes and crane spare parts that you need.