15 Ton Overhead Crane to Kenya - DQCRANES Reliable Overhead Crane Manufacturers

27 Dec, 2022

- Industry: Steel Pipe and Tube Manufacturers

- Application: Testing aisle

- Product Manufacturer: DQCRANES

- Import Country: Kenya

Project Description:

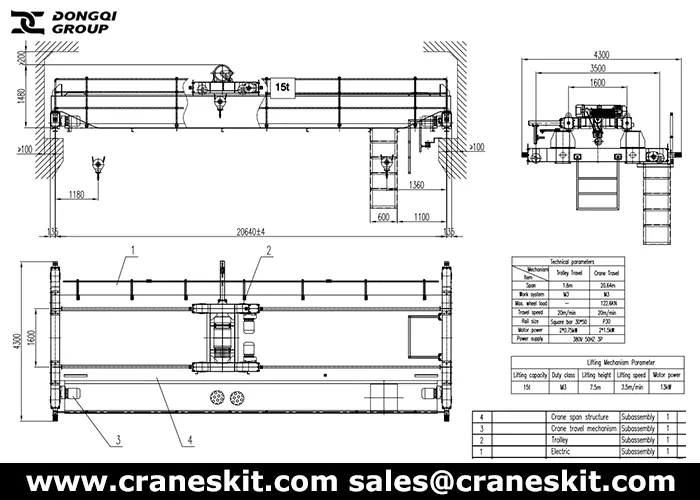

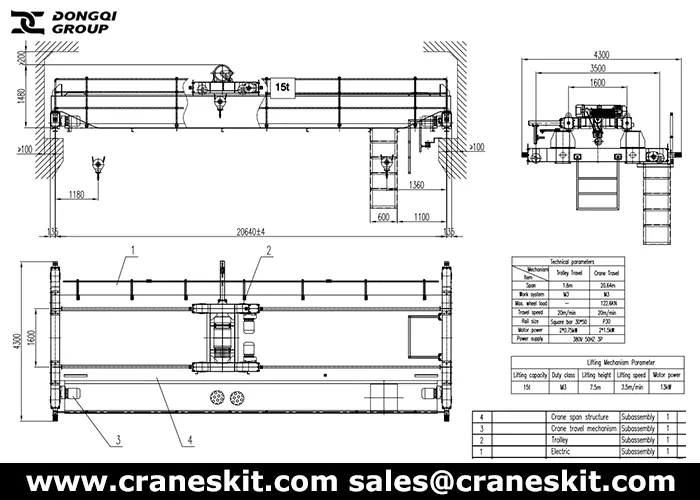

Project Description: - DQCRANES supplied a new 15 ton overhead traveling crane for a tube/pipe producer in Kenya.

- These two sets Double Girder Overhead Crane replaces an existing single girder EOT crane used in the customer’s testing department.

- The 4-motion severe service top running crane was designed to be installed on an existing runway system of 20.64 meters span and 7.5 meters of lift, 84 meters P30 running rails.

- The travel drive is designed with infinitely variable control and offers state of the art precision handling for extremely smooth control and minimal maintenance.

- The 15 ton overhead crane is equipped with an enclosed cab suspended from the main girder. Also equipped with remote control is included as a second mode of operation.

- Now the new top running overhead cranes have been packaged and exported to Kenya, hope everything goes well.

15 Ton Overhead Crane to Kenya Design Drawing and Parameters:

Overhead bridge cranes: Single Girder vs. Double Girder Design

- On a single girder crane at DQCRANES, the bridge consists of one girder beam supported on each side by an end truck. The trolley and hoist are most commonly underslung—meaning they run on the bottom flange of the bridge. The bridge itself can either be top running or under running in design.

- If properly designed, a single girder crane can be the perfect solution for a business that needs a light to medium duty crane, or for a facility where headroom and/or floor space is limited.

- Single girder bridge cranes are often the most cost-effective lifting solution for various applications and industries. Single girder cranes use less material and are more compact and lightweight than a Double Girder Crane, which results in a significant cost-savings in material, freight, and installation. Also, because they only require one bridge beam, these systems typically have less deadweight, meaning they can utilize lighter runway systems and tie into the existing building support structure.

Advantages of a Single Girder Crane Design from DQCRANES:

- Less expensive due to a simpler trolley design, reduced freight costs, simplified and faster installation, and less material for the bridge and runway beams.

- Most economical option for light to medium-duty cranes.

- Lower loads on the building structure or foundations due to a reduced deadweight. In many cases, it can be supported by existing roof structure without the use of additional support columns.

- Better hook approach for both trolley travel and bridge travel.

- Easier to install, service, and maintain.

- Ideal for workshops, warehouses, material yards, and manufacturing and production facilities.

- Lighter load on runway rails or beams means less wear on the beams and end truck wheels over time.

- Great for facilities with low headroom.

Double Girder Overhead Crane Design:

- On a double girder crane, there are two girder beams that make up the bridge and they’re supported by an end truck on each side. In most instances, the trolley and hoist run on a rail installed on top of the bridge girders. With a double girder design, you gain the depth of the cross girder if the hoist is placed between or on top of the cross girders—providing an extra hook height in most cases.

- double girder bridge cranes can be either top running or under running in design. A top running double girder bridge crane will provide the most overhead room, as well as the greatest hook height.

- Double girder running cranes are recommended for heavy-duty applications where the crane has to handle heavier capacities and longer spans. Because of this, the components of the crane system, including the hoist and trolley, are more complex in design—making double girder cranes more expensive than a single girder crane.

Advantages of a Double Girder Crane Design from DQCRANES:

- Greater hook height – how far above the floor the hoist will lift more than single girder).

- No limits to maximum span or capacity.

- Ideal for production and transportation of heavy equipment.

- Ideal for frequent lifting of heavy loads.

- Added features like walkways and maintenance platforms, cabs, magnetic reels, and lights can be added and supported by a double girder design.

- Can be used in indoor and outdoor applications, including mining, iron and steel, railyards, and ports.

If you are not sure about choosing single girder or double girder crane, welcome to

contact us for free consultation and quotation.

Double Girder Overhead Crane Manufacturer - DQCRANES

- Double girder overhead cranes supplied by DQCRANES are designed to handle larger capacities because they are robust and can be customized to your needs and application conditions.

- Double girder overhead crane with crane hook, grab bucket, magnetic force, pliers, and other lower hook devices, suitable for use in machinery manufacturing, auxiliary workshops of metallurgical plants, storage, warehouses, power stations, etc.

- Double girder overhead cranes or double girder bridge cranes are a lifting solution that can handle medium to heavy loads from 5 tons to 550 tons. Generally, double girder overhead cranes are recommended for handling weights greater than 10 tons.

- We are the most adaptable manufacturer of double girder cranes, offering a wide range of models to meet every lifting need. All of our double girder overhead cranes are built to order, which means they can be customized to any size and load capacity.

Get Overhead Crane Price For Your Application!

Because each customer's actual working conditions vary, the price of a bridge crane of the same tonnage will vary as well. The following elements contribute to the price difference: lifting capacity, span, lifting height, power supply, actual working environment, and unique requirements of the customer.

So, if you'd like to receive a reliable crane design and quote for an

overhead bridge crane that suits your needs, please confirm the following information:

- Lifting capacity: _ton?

- Span: _m?

- Lifting height: _m?

- Power supply: (e.g. 380V, 50Hz, 3Phase) or other request?

- Crane traveling length: _m?

- Application or working conditions of the crane?

- How many hours does the crane need to work each day?

- Shall we provide you the crane traveling rails?

- Other requirements?

At DQCRANES, we are a leading manufacturer of world-class overhead cranes with more than 20 years of experience. We engineer and build custom solutions ranging from light-duty economical cranes to large-capacity, high-duty cycle cranes. If you’re interested in receiving a quote on a new overhead crane system, or would like to schedule a consultation,

contact us today!

Related Products

![European Standard Double Girder Overhead Crane]() European Standard Double Girder Overhead Crane

European Standard Double Girder Overhead Crane![European Standard Double Girder Overhead Crane]() European Standard Double Girder Overhead Crane

European Standard Double Girder Overhead Crane![HD Electric Hoist Overhead Crane]() HD Electric Hoist Overhead Crane

HD Electric Hoist Overhead Crane![HD Electric Hoist Overhead Crane]() HD Electric Hoist Overhead Crane

HD Electric Hoist Overhead Crane