Overhead Crane Nigeria: 10 Ton Underslung Crane Installed in Steel Plant

07 Dec, 2022

- Our client is an engineering contractor, and he has undertaken a steel factory expansion project in the last six months. The person in charge of the steel plant needs several bridge cranes to help improve the efficiency of steel pipe transportation.

- After checking the photos of plant working environment, our sales engineer recommend underslung bridge crane to meet the client's requirement. DQCRANES under running crane is typically an underhung, single girder crane where the wheels ride or operate on the bottom flange of a runway beam or track. An electric wire rope hoist will ride on the lower flange of the bridge beam or track.

- Single girder underhung bridge cranes are typically adopted for lighter duty material handling with capacity to 10 ton or less. Our 10 ton underhung crane for sale to Nigeria, designed to improve crane safety and reduce load cycle times during production in client's plants.

10 Ton Underslung Crane to Nigeria: Production

4 Sets Under Running Crane Exported to Nigeria:

Crane Traveling

- Type: LX suspension crane

- Lifting capacity: 10 Ton

- Span: 22.5m

- Lifting height: 15m

- Travelling speed: 20 m/min

- Rail type: H 700*296*15*25mm, 9m*3pcs

- Travelling Motor : SZW-150

electric hoist

- Type: CD1 10 ton wire rope hoist

- Lifting speed: 8 m/min

- Lifting height: 15 m

- Lifting motor: ZD151-4

- Travelling speed: 20 m/min

- Hoist travelling Motor: ZDY.21-4

- Power supply: 3P 380V 50Hz

Crane Steel Structure:

Another problem: our customer also need steel structure of these 4 sets 10 ton under running bridge cranes. After communicated via emails and online video with our client, our engineers designed the

overhead crane and steel structure workshop according to the client’s requirements.

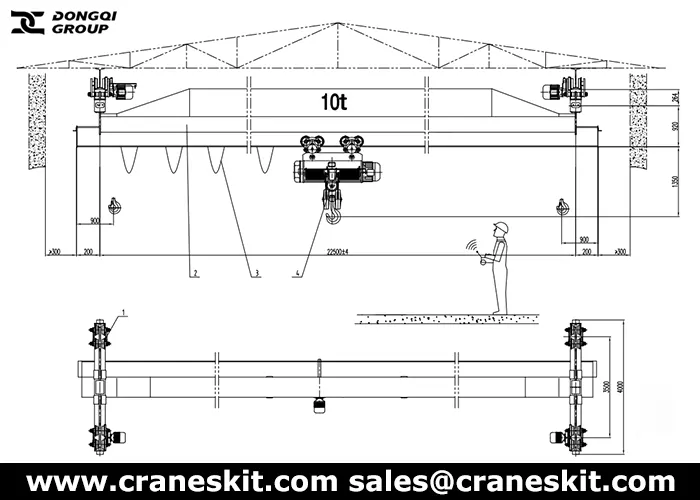

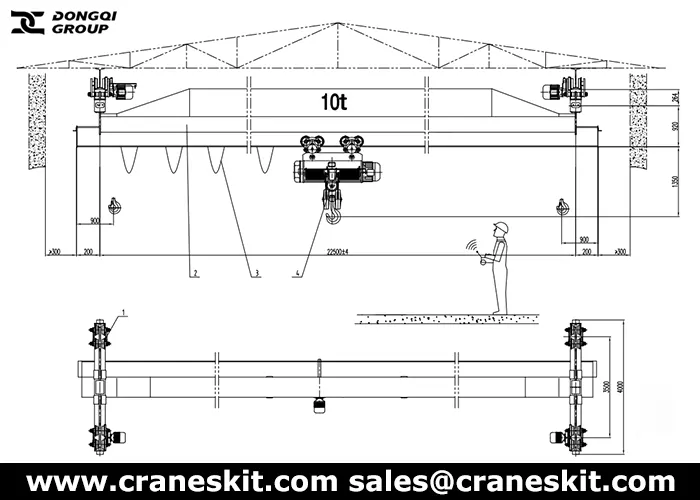

The following is design drawing of 10 ton underslung crane for sale to Nigeria, for your reference:

10 Ton Underslung Crane to Nigeria: Package and Delivery

Why Choose Under Running Overhead Crane?

With an underslung bridge crane, the runway beam is often attached and supported by the roof supporting structure, without the requirement of extra floor columns to support the runway. In this way, the underhung bridge crane can be advantageous if floor space and the requirement to reduce floor obstructions is a concern in the factory workshop or warehouse. An single girder underhung bridge crane may also be a good solution for workshops with sloped ceilings or with multiple crane systems.

Top Running vs. Under Running Cranes

- Except under running crane, we also supply top running cranes for your jobs. A top running overhead crane has a fixed rail or track system installed on the top of each runway beam—allowing the end trucks to carry the bridge and hoist along the top of the runway system. Top running cranes can be configured in a single girder or double girder bridge design. A single girder bridge utilizes an underhung trolley and hoist, while a double girder design most often utilizes a top running trolley and hoist.

- Top running overhead cranes have no limiting capacity—meaning that they can be built to handle small capacity loads or large capacity loads. Top running cranes can be built to capacities of anywhere from 1 ton to 550 tons. These types of overhead cranes are supported by the building structure or runway support columns and are ideal for moving extremely heavy loads.

- While motorized underhung bridge crane or under running bridge crane are the same type of single girder overhead crane. With the underhung bridge cranes design, the end trucks / end carriages move on the bottom flange of the runway beam unlike the top running overhead travelling cranes. Lifting capacity from 500kg to 10 tons.

- With an underslung bridge crane, the runway beam is often attached and supported by the roof supporting structure, without the requirement of extra floor columns to support the runway. In this way, the underhung bridge crane can be advantageous if floor space and the requirement to reduce floor obstructions is a concern in the factory workshop or warehouse. An single girder underhung bridge crane may also be a good solution for workshops with sloped ceilings or with multiple crane systems.

Get Your Custom Crane System from DQCRANES

One of the most common questions that we receive from customers during the consultation, design, and quotation process is whether they need a top running or under running overhead crane system.

At DQCRANES, we design and build overhead crane systems in every type of configuration imaginable. With so many different options available, careful consideration needs to be given to selecting a top running or under running crane configuration.

The following factors can help you determine whether a top running or under running system will be best for your facility and business needs:

- Can the existing support structure be utilized or will a new support structure need to be built?

- Are there existing runways in the facility that the crane can be installed on?

- What is the capacity of the loads that you’ll be lifting?

- What type of overhead room is available? High, or limited headroom due to existing cranes, etc.?

- How high will your lifts need to be?

- Hook approach – how much of the crane’s bridge will the hoist trolley need to utilize? Do you need to make picks or lifts near the edges or sides of the building?

If you’re interested in receiving a quote on a new overhead crane system,

contact us today to set up a free consultation.

Related Products