In the mechanical world, cranes are frequently to be seen in construction areas, in mining, logging, steel factory, plastic plant, warehouse and other applications for material handling. There is no exaggerate that industry cranes are the workhorse which have increased productivity and economic growth in their own ways. However, behind the splendid contribution made by various cranes, there are sacrifices caused by crane accidents. In order to avoid crane accidents from happening, the probable causes are analyzed and preventive measures are recommended for your reference.

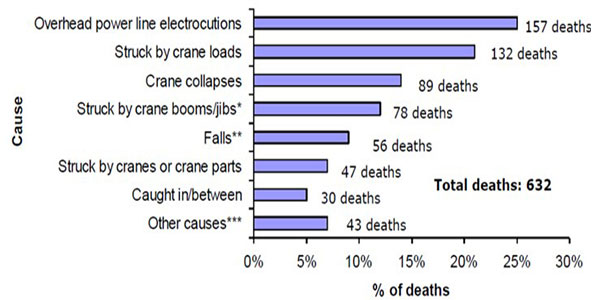

An industry crane can be a dangerous piece of equipment. Each and every year there are injuries and death occurred due to the crane accidents. According to the statistics of U.S Bureau of Labor Statistics, from 1992 to 2006, there were 632 death caused by crane accident in the construction area alone.

Causes of Crane-Related Deaths in Construction, 1992- 2006

*64 stuck by falling crane booms/jibs included.

** 21 falls from cranes, 9 falls from crane baskets, 8 from crane loads included.

*** 9 highway incidents are included in other causes.

Source: U.S. Bureau of Labor Statistics Census of Fatal Occupational Injuries Research File

From the above statics, the deaths mainly are caused by overhead crane power line electrocutions, struck by crane loads, crane collapses, struck by crane booms/jibs, and falls, etc.

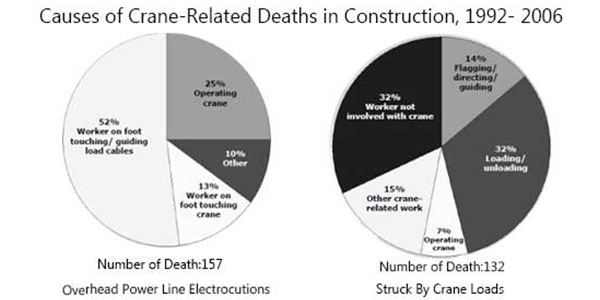

Among these causes, the electrocutions from overhead power lines takes away 157 people, which mainly caused by foot touching/ guiding loads cables, operating crane, foot touching crane, with the percentage of 52%, 25%, 13%, and 10 % for other reasons.

*64 stuck by falling crane booms/jibs included.

** 21 falls from cranes, 9 falls from crane baskets, 8 from crane loads included.

*** 9 highway incidents are included in other causes.

Source: U.S. Bureau of Labor Statistics Census of Fatal Occupational Injuries Research File

There were132 people who were died of being struck by crane load, which mainly happened during loading or un-loading, or caused by other crane related work, or happened during flagging, directing or guiding, or happened during crane operating, with the percentage of 32%, 15%, 14%, 7%. Even there were 32% of accidents happened to workers which were not involved with cranes.

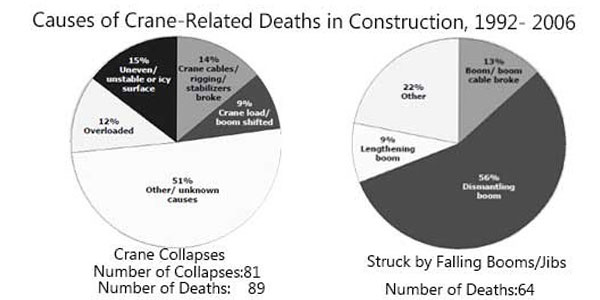

Crane collapse

From 1992 to 2006, there were 81 crane collapses, causing the deaths of 89 people. Among the 89 crane collapses, the main causes were unknown which takes 51% of the crane collapse cases, and the other left are caused by unstable surface such as uneven surface or slippy surface such as icy surface, or caused by broken crane cables or rigging or stabilizers, or caused by crane load or boom shift, with the percentage of 15%, 14%, 12%,and 9% respectively.

According to the statics, 64 people were killed by falling crane booms or jibs. The deaths of 64 peoples were caused by the striking of the dismantling boom, the broken boom or boom cable, lengthening boom, and others, with the percentage of 56%, 22%, 9%, and 22% respectively.

Mobile cranes took 71% of the crane accidents, which was mainly involved with the overhead power supply line accidents, crane collapses, and boom or jib cranes, taking the percentage of 84%, 63%, and 60 % respectively.

Tower cranes took 5% of crane related accidents, which were mainly caused by crane load accidents, and by jib striking.

There was 24% of crane accidents caused by floating cranes or unspecified cranes according to the statics. There are 13 floating crane accidents, 12 overhead crane accidents and 49 unspecified crane accidents involved.

Occupations of the death or injuries

According to statics, the construction laborers, heavy equipment operators including the crane operators, operating engineers, hoist operators, winch operators and other construction equipment operators, supervisors, mangers, iron workers, mechanics, and others such as welders, cutters, electrical workers, mechanics, sheet metal workers, trucker driver, etc., are exposed to the danger of crane accidents in the construction application. The specific diagram is presented for you reference.

Causes of Crane-Related Deaths in Construction, 1992- 2006

*62 crane and tower operators, 21 operating engineers and other construction equipment operators, and 7 hoist and winch operators.

** 24 welders, and cutters, 22 electrical workers, 21 mechanics, 17 sheet metal workers, 14 truck drivers, and 73 others.

According to study and statics, there are inherent hazards that may occur during the application environment. A crane is dangerous. Most of the crane accidents are attributed to several basic hazards. The general crane hazards can be classified in the following forms:

There are rare chance to change the design of a crane at the working site to make it safer, however, crane hazards are controllable if the crane operator and user take preventive measures:

1. Minimize or eliminate the hazards. During the crane designing projects, the hazards produced by particular work circumstances should be minimized or eliminated.

2. Guard hazard. Hazard that can not be totally eliminated should be minimized or reduced through appropriate measures to protect and monitor to prevent the hazards from being activated or triggered.

Preventive measures are recommended as follow:

3. Warnings. Warning devices should be installed to detect hazards and emit warning signal when the hazards can not be controlled by the above mentioned measures.

4. Special procedures and training. Special operating procedures, training and audits must be employed to guarantee that a viable, continuing regimen will effect avoidance of the hazard.

5. Personal protective equipment. Crane user, operators, and other related workers should wear proper protective equipment, such as, gloves, hard hats, safety shoes, aprons, goggles, safety glasses, life jackets, lifeline, taglines to guide the load, etc.

Power line contact is the inadvertent contact of any metal part of a crane with a high voltage power line.

Crane accidents preventive measures:

1) Pre-job planning is the most effective measure to avoid crane power line contact.

2) Designate a person in charge to pre-job planning because of large number of working staff engaged in the working place.

3) The crane power lines and the crane working area should not occupy the same area.

4) Visual guidance should be given to the crane operators and loads guiders, and those working closely with cranes about the dangerous zone where is within a radius of 10 feet in any direction from the crane power lines.

Crane overload is strictly prohibited. However, it occurs when to handle a loads exceeding the rated capacity of the crane. Then crane accident happens due to the upset or structural failure.

Crane accidents preventive measures:

1) Crane operators should be trained on planning and load measuring.

2) More advanced and precise devices such as solid-state micro-processing electronics and load-measuring systems should be installed on the crane to warn the occurring of overload and stop the operation automatically.

3) On job-training is necessary to crane operators even if they are all qualified.

Many cranes upset because of the causal use of outrigger, i.e. the operator cannot extend the outrigger because of the limited space or because the outrigger pads may be too small to stand the crane even on hard ground. Due to overloading, defective or placed on inadequate foundation, crane outriggers may collapse.

Crane accidents preventive measures:

1) Safeguards should be ready before the operation of the crane.

2) Aerial basked designs with limit switches should be installed to prevent the movement of boom until outriggers are extended and in proper place to prevent upset.

3) Well-designed blocking or cribbing is necessary under the outriggers when ground is soft or when the floats or pads of outriggers is inadequate.

4) The blocking used to support outriggers should be ensured to be strong enough to prevent crushing and shifting or toppling under load.

Two-blocking refers to the hoist block or hook assembly come into contact with the boom tip, resulting in the breaking of the hoist and hook line and the fall of the loads, risking the life of the workers below.

Crane accidents preventive measures:

1. An anti-two-blocking device can be installed. a) It could be a weighted ring around the hoist line. It is suspended on a chain from a limit switch attached to the boom tip. B) It also can be a wired to intercede and stope the hoisting and stop the hoisting.

2. As for hydraulic cranes, the hydraulic valving will help the hoist line out when the boom is being extended to avoid two blocking.

3. Adequate boom length can effectively avoid the contact of hook and the headache ball with boom tip for it can provide accommodate both the boom angle and sufficient space for rigging.

Pinchpoints can come into two ways:

1. Within the swinging radius of the rotating superstructure of a crane is areas where people may be injured between the carrier frame and the crane cab, or between the crane cab and an adjacent wall or other structure.

2. The gears, belts, rotating shafts, etc., without safety guard within the crane are the pinch points which many injured people.

Crane accidents preventive measures:

1. The swing area of the crane cab and counterweight must be isolated with barriers to prevent entry.

2. Reduce the incentives such as water jugs, tool boxes, and rigging materials from crane cabs to prevent pinching.

3. Rear view mirrors installed can help crane operator to get a better view to the turning area of the cab and counterweight to get a better safety.

The safety of crane operation will be compromised by the obstruction of vision when the crane operator can not see what the operator, rigger, or signaler is doing, which may injure people by the moving loads or the crane.

Crane accidents preventive measures:

1. Pre-job conference and planning and preventive measures are the most effective way to prevent crane accidents.

2. Radios and telephones should be used to assist the signalers to overcome the hazards of blind spots produced during loading, etc.

3. Automatic travel alarms is an effective to warn those in the immediate vicinity of crane travel movement in pick-and-carry functions.