gantry crane is a kind of

bridge crane, which adopts a gantry system composed of columns, beams and trolley mechanisms. These cranes are widely used for lifting and moving heavy objects or materials within facilities or construction sites. European standard gantry cranes are known for their excellent quality, safety and reliability. Adherence to strict European standards ensures that the cranes meet or exceed industry requirements.

Background

The construction industry in Qatar has been growing at a rapid pace in recent years. As a result, there has been an increasing demand for heavy machinery and equipment to help with the construction of buildings and infrastructure. One such machinery is the gantry crane, which is used for lifting and moving heavy loads. Recently, DQCRANES supplied a 10 ton gantry crane to Qatar, used for lifting concrete precast parts.

Client's Challenge

Our client was a construction company in Qatar that was involved in the construction of a large building project. They needed a crane that could lift and move heavy concrete precast parts, which were an essential component of the project. The precast parts were of varying sizes and weights, ranging from 5 to 10 tons. The client's challenge was to find a crane that could handle these heavy loads safely and efficiently.

Our Solution

After discussing the client's requirements and assessing the site via online video, we recommended a European Standard 10 Ton Gantry Crane for their reference. We sent the design drawings and detailed technical parameters to the client. The client replied needed to be checked with their engineer and gave us feedback within three days. Three days later, we received customer feedback that the span needs to be adjusted from 12 meters to 15 meters, of course, no problem. We have updated the latest design scheme and quotation, and the customer is very satisfied.

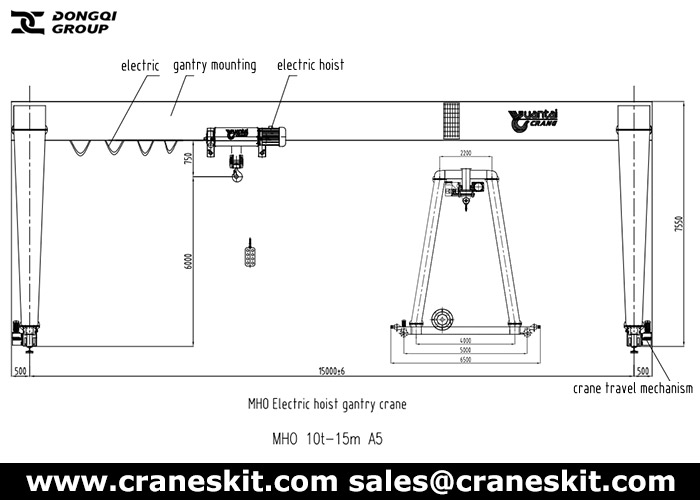

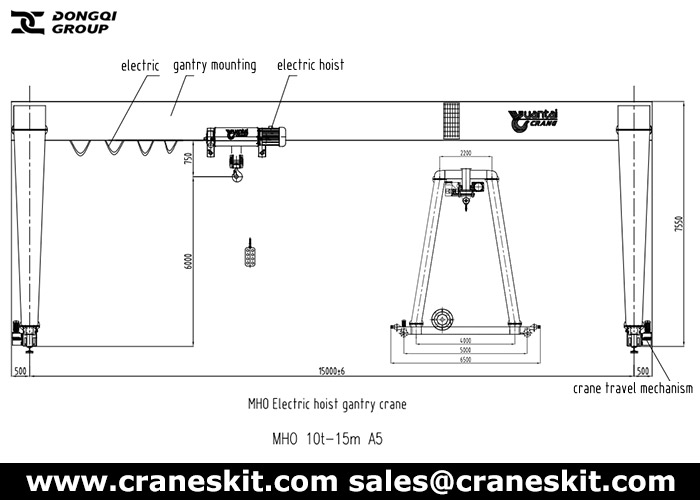

Design Drawing and Technical Parameters

- Lifting capacity: 10 tons

- Span: 15m

- Lifting height: 6m

- Working class: A5

- Hoist lifting speed: 0.4-4.0m/min

- Hoist traveling speed: 2.0-20m/min

- Crane traveling speed: 4.0-40m/min

- Control type: Ground control

- Power supply: 380V/50Hz/3phase

Crane Production and Delivery

Once the client approved our recommendation, we began the production of the

single girder gantry crane. Our team of engineers worked tirelessly to ensure that the crane was built to the highest standards. We used only the best quality materials and components to ensure the crane's durability and longevity. After production was complete, we shipped the crane to Qatar, where it was received by the client.

Crane Installation

Once the client receives the gantry crane, our team of technicians will travel to Qatar to install the crane on-site. We will work closely with the client's team to ensure that the installation process goes smoothly. We also provide training to the client's team on how to operate the crane safely and efficiently.

Why Buy Gantry Cranes from DQCRANES?

Structural stability

- At DQCRANES, our gantry cranes are designed with a sturdy structure, usually with two columns supporting the crossbeams. This structure allows the crane to have excellent stability, able to withstand significant loads and ensure safety and reliability during lifting operations.

Large load capacity

- Our outdoor gantry cranes have excellent load carrying capacity and are capable of handling a variety of heavy loads. Its structural design and the use of engineering-grade materials enable it to meet the major challenges and meet the needs of large-scale material handling.

Large working range

- Our heavy duty gantry cranes have a wide working range that can cover large lateral and vertical distances. This allows the crane to handle materials in a wide range of sites, meeting the needs of different work environments.

Precise positioning capability

- The gantry crane for sale is equipped with precise positioning systems for precise control and positioning of materials. Whether vertical lifting or horizontal movement, the crane can achieve accurate position positioning through precise operation, improving efficiency and safety.

Customizability

- Gantry cranes are highly customizable and can be designed and manufactured according to specific needs. Depending on the size of the work site, load requirements, and specific application needs, various custom configurations can be made to meet different industry and operational requirements.

Operational Flexibility

- The operational flexibility of gantry cranes allows operators to easily control the movement of the crane. Equipped with an advanced control system and user-friendly operator interface, operators can accurately and safely control lifting, lowering, and traveling crane movement, and material location to improve operational efficiency.

Safety features

- Gantry cranes are equipped with a variety of safety features, such as overload protection devices, travel limit switches, emergency stop buttons, and anti-collision systems. These safety features ensure the safety of the crane during operation, protecting the operator, the equipment, and the surrounding environment from potential risks. Regular maintenance and inspection are also important measures to ensure the safety performance of the crane and should be carried out regularly to maintain the proper operation and safety of the crane.

Environmental adaptability

- Gantry cranes are highly adaptable to the environment. Whether indoor or outdoor, whether dry factory workshop or wet port terminal, portal cranes are able to adapt to a variety of working environments. Its structural design and the choice of weather-resistant materials enable it to withstand harsh weather conditions and corrosion, ensuring long-term reliable operation.

Ease of maintenance

- Gantry cranes are typically simple in design and easy to maintain. Key components and systems are easily serviced and replaced, reducing maintenance time and costs. In addition, the availability of regular maintenance programs and service support ensures good operating conditions and long service life for the crane.

Multiple working conditions

- Gantry cranes are suitable for a wide range of working conditions, including heavy industry, manufacturing, aerospace, ports, and logistics. Whether moving heavy machinery parts, loading and unloading cargo, stacking materials, or maintenance equipment, portal cranes are able to adapt to different work requirements.

If you have interests or request a free quote, please feel free to

contact us. Dongqi as a professional gantry crane manufacturer, will help you find out the optimal gantry crane for your application at good price!