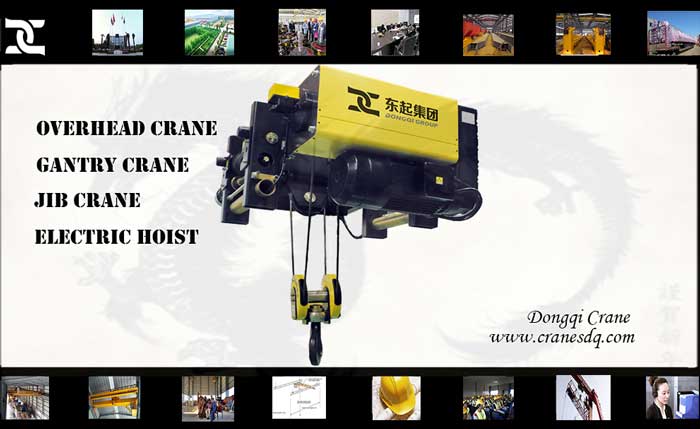

European wire rope electric hoist is a newly developed material handling equipment with advanced design technology according to the FEM standards and other regulations. The new serial of wire rope electric hoist is environment-friendly, energy saving and cost-effective which ranks top among similar products. The lifting capacity of the European wire rope electric hoist is 1 to 80 tons and the working class is M5 and M6. Customized European wire rope electric hoist are available. And the main parameters are presented for your reference.

| Product Type | ND |

|---|---|

| Lifting Capacity | 1~80t |

| Lifting Height | 6~50m |

| Working Class | M5, M6 |

| Ambient Temperature | -20~40℃ |

The features of European wire rope electric hoist are as follow:

Single girder hoist up to 12.5 ton

Due to the design, hoist motor, gear box and drum are arranged scientifically and compactly which enlarges the working space of crane and increases the lifting height. Based on FEM calculations for standard lifting gear, the electric hoist can lift loads form 1 to 80 tons, with the features of smooth and silent operation, extended working life, lift-time lubrication and double surface DC brake, etc.

Single girder hoist up to 12.5 ton Double girder hoist up to 80 ton

The hoist is equipped with double speed changing squirrel cage motors or equipped with frequency converter motor for variable speed control.

The hoist is equipped with double speed changing squirrel cage motors or equipped with frequency converter motor for variable speed control. Sealed gearbox housing are made of aluminum. Gears run in totally enclosed semi-fluid or oil bathe lubrication, designed for the lifetimes of the crane.

Sealed gearbox housing are made of aluminum. Gears run in totally enclosed semi-fluid or oil bathe lubrication, designed for the lifetimes of the crane. DC magnetic disk brakes are equipped to hoist motors which are adjustment free and are designed and manufactured to work together so that the load will not slip when starting, lowering or stopping, etc.Hoist brake is fully covered and is dust proof.+

DC magnetic disk brakes are equipped to hoist motors which are adjustment free and are designed and manufactured to work together so that the load will not slip when starting, lowering or stopping, etc.Hoist brake is fully covered and is dust proof.+ The hoist drum is made from high quality steel tubing and has precise grooved for the rope to prevent rope overlap.

The hoist drum is made from high quality steel tubing and has precise grooved for the rope to prevent rope overlap.The cross travel drives can withstand unfavorable conditions such as low power supply and aggressive surroundings. The travel motors are equipped with DC magnetic disk brakes which is adjustment free. All motors comply with related standards, such as, CE, VDE, DIN, UL/CSA, CCC, ETC. Single and double speed drives are also available.

In order to keep the hood from over travel, the adjustable geared and self re-setting hoist and lower limit switches are provided. Automatic cut-off during the lifting and lowering motions in upper and lower limit positions are realized.

In order to keep the hood from over travel, the adjustable geared and self re-setting hoist and lower limit switches are provided. Automatic cut-off during the lifting and lowering motions in upper and lower limit positions are realized.

The wire rope hoist can be equipped with a safety monitoring unit, with the features of practical, easy to use and sophisticated, which will stop hoist when overload of the hoist or overheating of the motor occur to increase safety and optimize maintenance.