Introduction

Saudi Arabia's ambitious Vision 2030 initiatives are driving an unprecedented boom in infrastructure, industrial, and urban development. This rapid expansion demands robust, reliable, and high-capacity lifting solutions to facilitate the construction of complex and large-scale projects. DQCRANES, a global leader in crane manufacturing and engineering, was strategically chosen to deliver a critical lifting solution for a significant outdoor construction project in the Kingdom. This case study details the design, manufacturing, and installation of a 25-ton and a 50-ton rail mounted

gantry crane, engineered to meet the unique challenges and demands of the Saudi Arabian construction environment.

Client Background

Our client, a leading EPC contractor in Saudi Arabia, was at the forefront of a significant construction initiative. Their project involved the development of a large industrial complex, requiring continuous and precise handling of extremely heavy and oversized components across extensive outdoor yards. The sheer scale and long-term nature of the work necessitated a permanent, highly efficient, and durable lifting solution that could withstand the demanding local environment.

The Challenges

- Massive Scale & Outdoor Operations: The project involved handling exceptionally large and heavy precast concrete elements, steel structures, and other critical components across vast outdoor yards and active construction zones. Traditional mobile cranes lacked the consistent lifting capacity, reach, and cost-effectiveness for long-term, high-volume operations.

- Precise Positioning Requirements: Many components required highly accurate placement, demanding a rail mounted gantry crane capable of smooth, controlled movements and precise positioning over extended distances.

- Harsh Environmental Conditions: Saudi Arabia's climate presents significant challenges, including high temperatures, dust, and the potential for sandstorms. The cranes needed to be designed and built to withstand these conditions, ensuring operational reliability and longevity.

- Operational Efficiency & Safety: Maximizing operational efficiency while maintaining the highest safety standards was paramount. The client required a solution that could significantly reduce project timelines and minimize risks associated with heavy lifting.

- Long-Term Durability & Low Maintenance: Given the project's extended duration and the critical nature of the lifting tasks, the client sought a solution that would require minimal downtime for maintenance and offer a long operational lifespan.

Gantry Crane Saudi Arabia Solution from DQCRANES

DQCRANES' engineering team undertook a comprehensive analysis of the client's requirements, site conditions, and operational workflow. Based on this assessment, a dual-crane solution featuring two custom-designed rail-mounted outdoor gantry cranes was proposed and accepted:

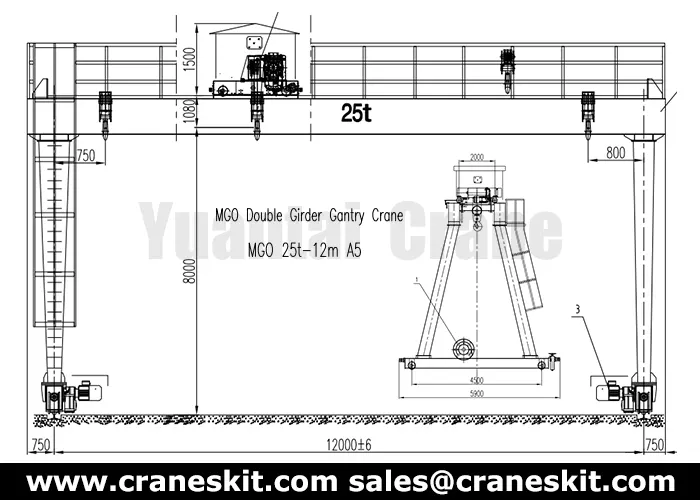

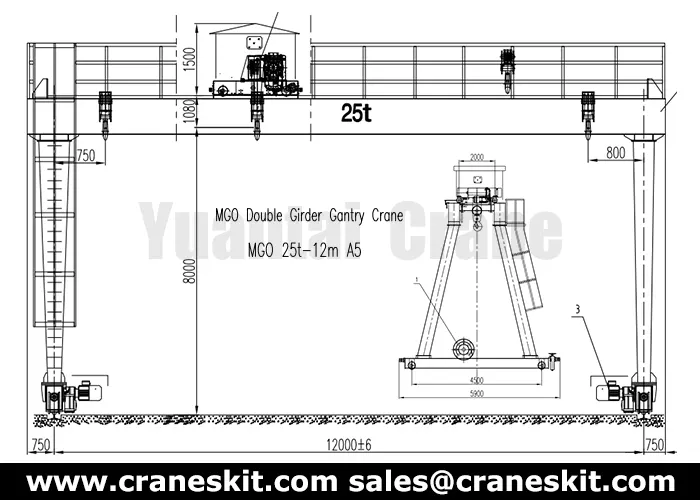

25 ton gantry crane:

- Capacity: 25 tons (25,000 kg)

- Span: 12 meters

- Lifting Height: 8 meters

- Lifting Speed: 0.43~2.8 m/min

Application: Primarily for handling medium-to-heavy precast elements, assembling steel frameworks, and transporting materials within designated areas. Its agility and speed made it ideal for tasks requiring frequent movements.

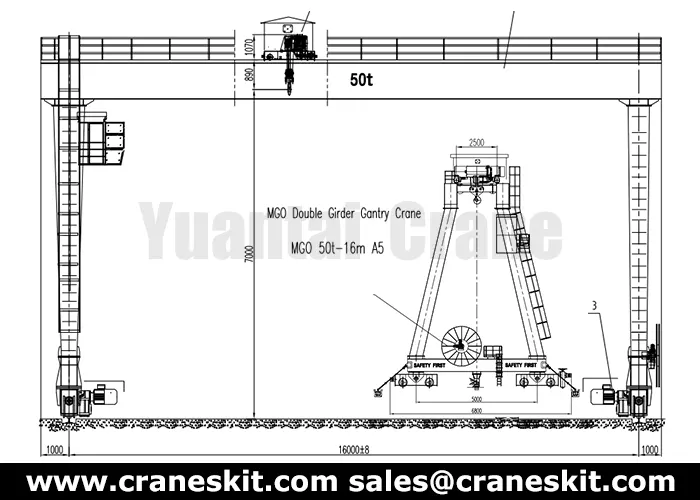

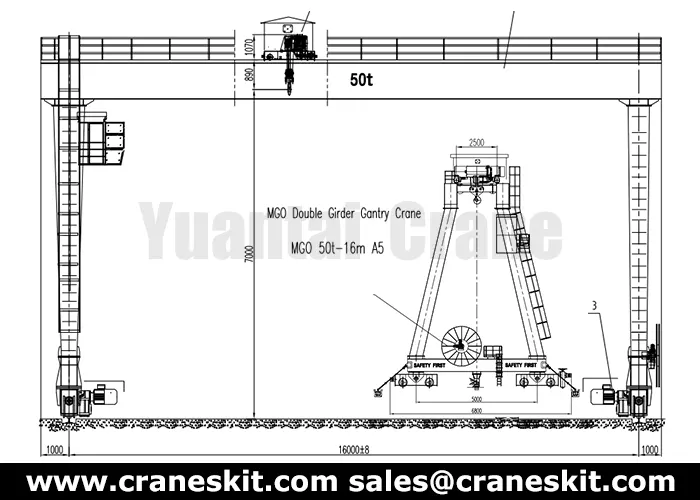

50 Ton Gantry Crane:

- Capacity: 50 tons (50,000 kg)

- Span: 16 meters

- Lifting Height: 7 meters

- Lifting Speed: 0.7~4.1 m/min

Application: Dedicated to the heaviest lifting tasks, such as maneuvering massive structural beams, large machinery components, and large-span precast sections. Its robust design ensured stability and precision for critical lifts.

RMG Crane Design Features:

- Robust Double Girder Structure: Provides exceptional rigidity, strength, and stability, crucial for handling heavy loads and wide spans.

- Weather-Resistant Electrics & Components: All electrical panels, motors, and control systems are housed in IP55 (higher optional) rated enclosures, protecting them from dust, moisture, and high temperatures.

- High-Performance Hoisting Mechanisms: Equipped with advanced FEM standards electric trolley hoists, providing smooth, multi-speed lifting and lowering for precise load control.

- Advanced Corrosion Protection: Multi-layered, high-quality industrial paint systems and specialized anti-corrosion treatments were applied to all steel structures to combat the harsh, saline-rich (if near coast) or dusty environment.

- Variable Frequency Drives (VFDs): Integrated VFDs on all crane motions (hoisting, trolley, and long travel) ensure smooth, stepless speed control, reducing mechanical wear, enhancing precise load positioning, and improving energy efficiency.

- Comprehensive Safety Systems: Equipped with:

Overload protection devices

Limit switches for all motions (hoist, trolley, long travel)

Emergency stop buttons

Anti-collision systems

Audible and visual alarms

Rail clamps for storm conditions

- Ergonomic Operator Cabin: Air-conditioned (essential for KSA), fully enclosed cabin with wide visibility windows, comfortable seating, and user-friendly controls to ensure operator comfort and safety during long shifts.

- Heavy-Duty Wheel Groups: Designed with large diameter, hardened wheels for smooth, long-distance travel on rails, minimizing wear on both wheels and rails.

- Rail System Design & Integration: DQCRANES provided detailed specifications for the rail foundation and installation, ensuring proper alignment and stability for the RMGs to operate effectively over long distances.

- Ease of Maintenance: Designed with accessible maintenance points and standardized components to facilitate routine inspections and servicing, minimizing downtime.

Gantry Crane Installation in KSA

Upon arrival, a dedicated team of highly skilled DQCRANES engineers and local technicians commenced the on-site gantry crane installation. This intricate process involved:

- Site Preparation & Rail Verification: Ensuring the prepared rail foundations were perfectly level and aligned to support the massive cranes.

- Structural Assembly: Meticulously assembling the main girders, supporting legs, and end carriages using specialized lifting equipment and strict safety protocols.

- Mechanical & Electrical Integration: Installing the hoists, trolleys, control cabins, and connecting all electrical systems.

- Precision Alignment: Expertly positioning the cranes onto their rail tracks, ensuring optimal alignment for smooth and reliable travel.

- Rigorous Testing & Commissioning: Conducting comprehensive static and dynamic load tests, verifying all safety features, and calibrating the control systems to ensure optimal performance and adherence to all local and international safety regulations.

- Operator Training: Providing extensive hands-on training to the client's local operators and maintenance staff, covering safe operation, daily checks, troubleshooting, and basic maintenance.

After-Sale Service:

After-Sale Service:DQCRANES' commitment extends far beyond installation. We understand that consistent performance is vital for large-scale construction projects. Our after-sales service package for the Saudi Arabian client includes:

- Preventive Maintenance Programs: Scheduled inspections and maintenance to identify and address potential issues before they cause downtime.

- Spare Parts Availability: Ready access to genuine spare parts ensures quick replacements and minimal disruption.

- Technical Support: Remote and on-site technical assistance from our expert engineers for any operational or maintenance queries.

- Modernization & Upgrades: Future options for upgrading components or systems to extend crane lifespan and enhance capabilities.

Client's Feedback

"DQCRANES proved to be an invaluable partner for our critical construction needs in Saudi Arabia," stated the Project Manager, "Their expertise in designing and delivering such high-capacity

double girder gantry cranes, perfectly adapted to our challenging environment, has significantly accelerated our project timelines and enhanced our operational safety. The seamless installation and comprehensive after-sales support give us immense confidence in our heavy-lifting capabilities."

Conclusion

The successful deployment of the 25-ton and 50-ton heavy duty RMG cranes by DQCRANES for this vital Saudi Arabian construction project exemplifies our commitment to engineering excellence and client satisfaction. DQCRANES not only provided powerful and reliable crane equipment but also a comprehensive crane service to ensure operational excellence. This project further solidifies DQCRANES' reputation as a trusted partner for heavy-duty lifting requirements in the rapidly growing markets of the Middle East.

How to Buy Gantry Cranes in KSA?

DQCRANES offers a streamlined process for clients in Saudi Arabia to acquire our high-quality gantry cranes:

- Initial Inquiry: Contact us via our official website, email, or phone. Provide basic details about your project, required crane type, basic specifications, and location in KSA.

- Detailed Consultation & Site Assessment: Our expert engineers will engage in a thorough discussion to understand your specific operational needs, site conditions, load types, and environmental factors. We may request site plans or arrange a visit (virtually or in person) if necessary.

- Customized Solution Proposal: Based on the assessment, DQCRANES will provide a detailed proposal, including recommended crane specifications, design features, technical drawings, and a comprehensive quotation.

- Manufacturing & Quality Control: Upon agreement, your crane will be manufactured in our advanced facilities, adhering to the high-quality standards and international certifications. You may receive updates on the manufacturing progress.

- Logistics & Delivery: We handle all aspects of shipping and customs clearance, ensuring efficient and secure delivery of your crane components to your project site in Saudi Arabia.

- Professional Installation & Commissioning: Our certified installation team will travel to KSA to assemble, erect, test, and commission the crane, ensuring it is fully operational and compliant with all safety regulations.

- Operator Training & After-Sales Support: We provide thorough training for your personnel and offer long-term after-sales service, including maintenance, spare parts, and technical support.

Choose DQCRANES for reliable, high-performance gantry cranes that elevate your construction capabilities in Saudi Arabia and the Middle East.