Crane girder includes overhead crane girder and gantry crane girder. Overhead crane girder has overhead crane single girder and overhead crane double girder. While gantry crane girder has gantry crane single girder, gantry crane double girder and gantry crane truss girder.

Crane girder mainly use box-type structure and truss structure, while the box-type structure crane girder is the most widely used.

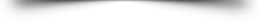

Crane Girder Structure

Overhead crane usually used box-type structure girder. The box crane girder consists of upper and lower cover plates and two vertical cover plates, which are closed box-shaped section structures. In order to reduce the weight and make of equal strength beam, the lower edge of the web and the lower cover should be made of parabolic shape. However, to facilitate the production, usually the middle of the web is rectangular, and both ends are trapezoid, so that the lower cover can be tilted at both ends.

Overhead Crane Girder

The box-type crane girder can adopt the whole steel plate welding, which is easy to use active welding and semi-active welding. It has the advantages of simple planning, good fabrication technology and suitable for batch production. It is the most widely used construction method.

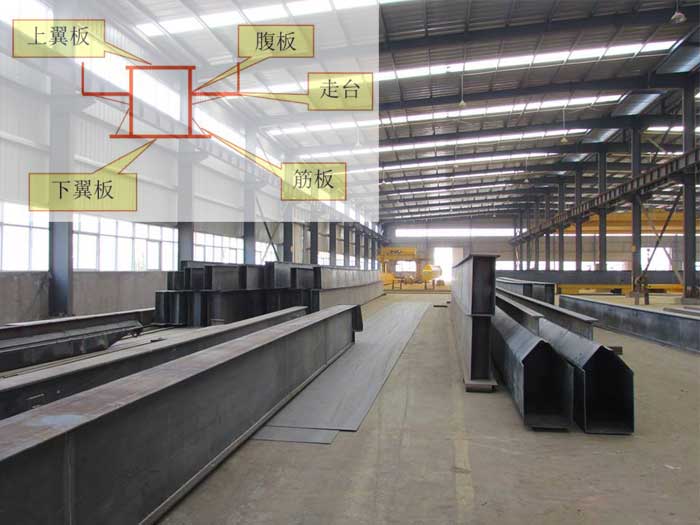

The crane girder has the following effects on the camber:

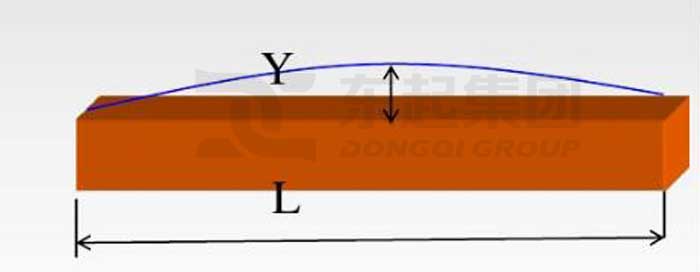

The down-warping of the crane main beam is the permanent deformation of the bending of the crane main girder, from the original height.

The main reason for the serious down deflection of the crane girder is:

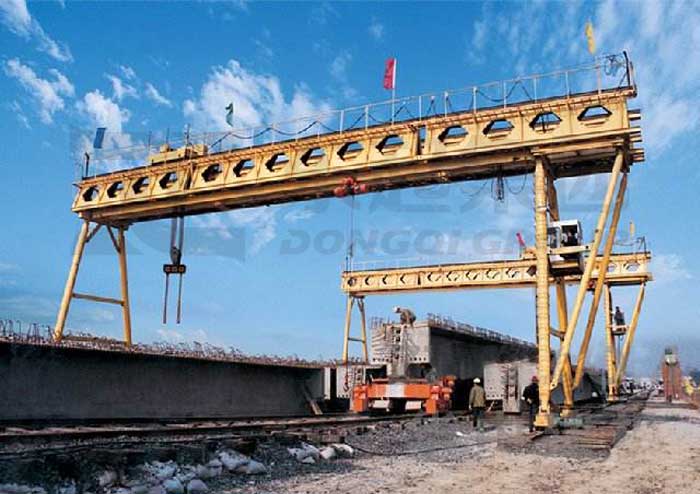

Usually the main girder structure of gantry crane has truss beam, box girder and honeycomb beam.

Gantry crane truss beams are usually made of angle steel or I-beam through welding process. Although it has the advantages of low cost, light weight and good wind resistance, the truss has the disadvantages of large surrounding degree and small rigidity due to many welding points and defects of the truss itself, low security and stability, the need for frequent testing of solder joints and other shortcomings.

Gantry Crane Truss Girder

Gantry crane box girder is mainly made of steel plate or I-beam welded steel processing box structure, which has the advantages of high safety and reliability, stiffness and other advantages, but the gantry structure of the gantry crane high cost, heavy, the deficiency of relatively poor wind resistance.

Gantry Crane Box Type Girder

The main face of the honeycomb beam is isosceles triangle, on both sides of the waist have honeycomb holes, upper and lower chords. Honeycomb beams have the advantages of truss girders and box girders, but the honeycomb beams are welded with steel plates, so the dead weight and the cost are higher than the truss beams.

Gantry Crane Honeycomb Beam

Crane girder is the foundation of the crane. Dongqi Group can provide you crane girder design service. Also we can supply you overhead crane, gantry crane and crane spare parts.