The crane bus bar is used to supply power to the moving equipment. It consists of two parts. The slip rail (fixed part, connected with the power supply, the long rail is connected by a single length of 4m / root or 6m / root); Sliding part ( can slide in or on the slide track and contact with the copper strip to take power, the collector used to connect with the mobile motor).

At present, the general use of crane bus bar (tube, closed), unipolar combination of crane bus bar, rigid body crane bus bar, multi-stage pipe safety crane bus bar, seamless crane bus bar, cable crane bus bar, I-beam cable pulley, etc. Crane bus bar insulation has greatly improved in the protection level, safe and reliable.Two most commonly used forms of conductor system are: enclosed and parallel.

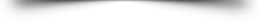

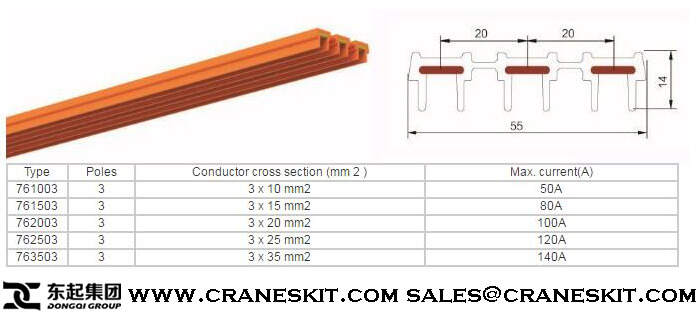

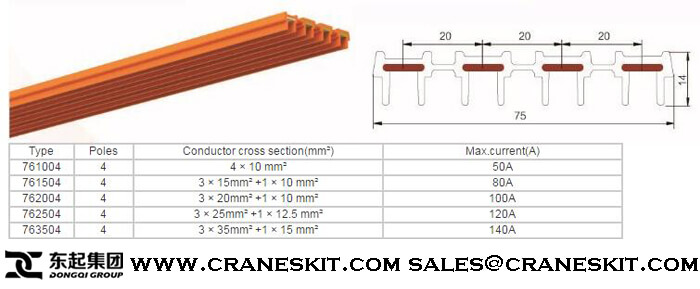

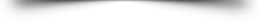

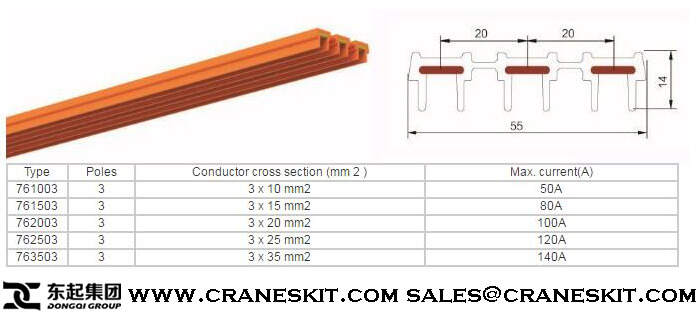

Technical Data of crane bus bar 3P 4P 6P

KM 3P Power Rail/Slide Wire/Conductor Line/HXTL

KM 4P Power Rail/Slide Wire/Conductor Line/HXTL

KM 6P Power Rail/Slide Wire/Conductor Line/HXTL

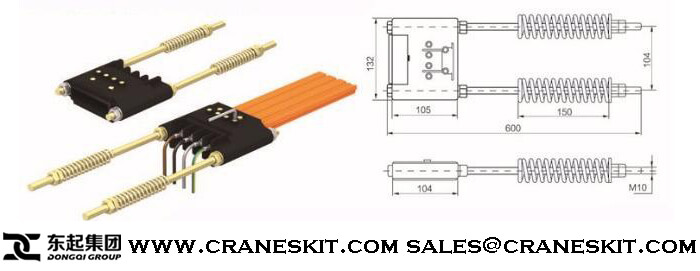

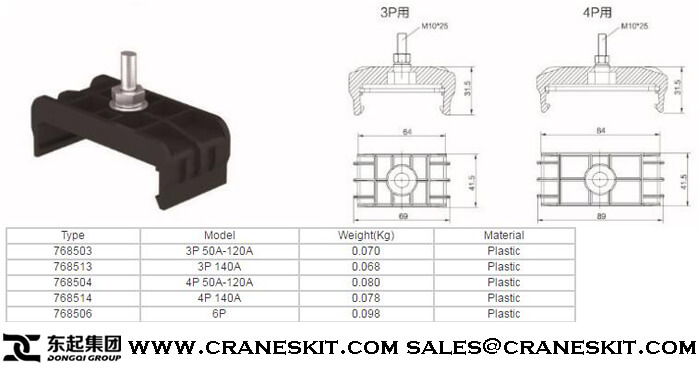

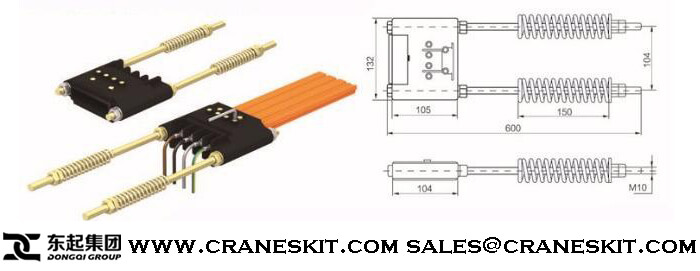

Accessories of crane bus bar 3P 4P 6P

Hanger Clamp

Current Collector

End Tension Show

Crane Bus Bar Advantages

- Installation and maintenance is simple and straightforward.

- Safe, reliable even in the harshest climates such as heavy rain, snow, of frost.

- Great electrical conductivity while dissipating heat quickly.

- Low impedance, minimum line loss.

- Graphite brush with high electrical conductivity and wear resistance

- Long use life

Crane Bus Bar Applications

Power plant, warehouse, port and dock, metallurgy, petrochemical, petroleum, textile, photograph industry, and amusement equipment.

Crane bus bar quality can be measured on the following criteria:

- carbon brush life - are consumables, travel distance affect the equipment maintenance cycle.

- trolley wire shell quality - for temperature, environment and so on.

- collector performance - mainly from the wheel life, turn wheel design and collector whether to meet the use of a variety of environments.

- trolley line expansion problem - the length of more than 100 meters after the expansion of the problem should be considered.

- the voltage drop problem - according to a variety of copper strip length voltage drop is different.

Related:

overhead crane

gantry crane

jib crane

electric hoist