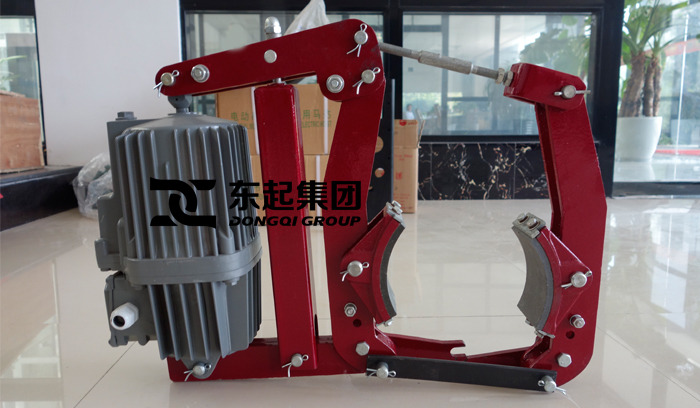

crane brake is mounted on the shaft of the motor and is used to brake the operation of the motor so that its operation or hoisting mechanism can be accurately and reliably stopped at a predetermined position. Crane brake has become an indispensable part of the power-driven crane mechanism.

Although the crane brakes vary according to the type of job requirements, the function in the gantry crane is the same. It’s mainly by controlling the rotation of the motor and the inertia movement so that the control device can be parked, accelerated or decelerated in a state of motion.

In conclusion, a crane brake not only serves a control purpose, but also functions as a safety device. With the brake, a hoist can speed up or slow down its vertical motion as well as control the rising or lowering goods to stop stably at a required height. Another use of the brake is in the crane traveling or luffing mechanism, where it allows the mechanism to stop at a pre-set location.

Crane brake can apply to transformer, storage and logistics, machining, nuclear power, aerospace, nuclear power, wind power, automobile, waste management, papermaking, steel, material handling, metallurgy, and petrochemical industries.

(Single-phase brake); spring-type long-stroke solenoid double brake shoe brake, referred to as long-stroke brake (three-phase brake); hydraulic putter (single-phase brake) Type double brakes brake, referred to as push rod brakes three. Brakes in the crane plays an important role in escorting, it can be said that if the crane does not install the brake device, then, as the car does not have the same brake function, the role of inertia in the parking is a serious risk hidden danger.

The role of crane brakes in the equipment is so important that we need to use during the daily life of the brake maintenance to pay more attention: to regularly check whether the brake is working in good condition. Should be found the existing security risks and reduce the crane accident rate. Through the sound to identify the brake device is abnormal and so on. Whether the wear and tear situation of the internal brake on the regular inspection is beyond the allowable range, whether the spring is failure, the internal parts of the dirt have too much and so on. If so ,it should clean up or replace internal devices timely.

More information about crane parts,overhead crane,gantry crane,jib crane,electric hoist,stay tuned as we develop more new technology and new products.