Types of cranes and classifications

20 Apr, 2016

A crane is a machine which is having a hoist with a longitudinal and cross movement. The hoist of a crane consists of wire rope and hook. The crane is used both for lifting and lowering materials, and to move them horizontally. Cranes uses one or more simple machines to create mechanical advantage and thus move heavy loads. Many factors are taken into consideration while selecting a crane. These factors include lifting capacity, crane use and application and the number of work cycles that the crane is required to undergo.

Cranes are of many types. Some of them are given below.

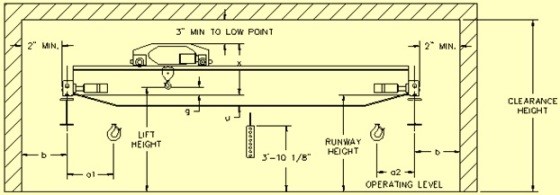

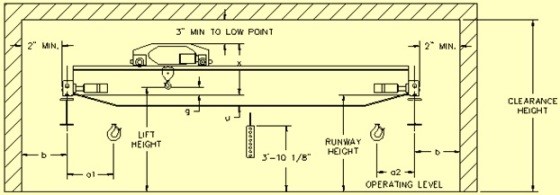

- overhead cranes – An overhead crane is also known as a bridge crane. It is a type of crane where the hook and the line mechanism runs along a horizontal beam that itself runs along two widely separated rails usually in a long factory building and runs along rails along the building’s two long walls. These cranes include a hoist to lift the items, the bridge, which spans the area covered by the crane, and a trolley to move along the bridge. Overhead cranes typically consist of either a single beam or a double beam construction. These can be built using typical steel beams or a more complex box girder type. double girder bridge cranes are more typical when needing heavier capacity systems from 10 tons and above. The advantage of the box girder type configuration results in a system that has a lower deadweight yet a stronger overall system integrity. A typical overhead crane is shown in Fig 1.

Fig 1 A typical overhead crane

- gantry crane – A gantry crane has a hoist in a fixed machinery house or on a trolley that runs horizontally along rails, usually fitted on a single beam (mono-girder) or two beams (twin-girder). The crane frame is supported on a gantry system with equalized beams and wheels that run on the gantry rail, usually perpendicular to the trolley travel direction. This crane comes in all sizes, and some can move very heavy loads.

- Mobile crane – Mobile crane is mounted on a carrier usually a truck which provides the mobility for this type of crane. This crane has two parts namely (i) a carrier which is often referred to as the Lower and (ii) a lifting component which includes the boom also referred to as the Upper. These are mated together through a turntable which allows the upper to swing from side to side. Modern hydraulic truck cranes are usually single engine machines, with the same engine powering the undercarriage and the crane. The upper is usually powered via hydraulics run through the turntable from the pump mounted on the lower. Older hydraulic truck cranes had two engines. One in the lower is used for the crane to travel on the road and ran a hydraulic pump for the outriggers and jacks. The second in the upper ran the upper through a hydraulic pump of its own. Generally, these cranes are able to travel on highways, eliminating the need for special equipment to transport the crane. When working on the job site, outriggers are extended horizontally from the chassis then vertically to level and stabilize the crane while stationary and hoisting. Many truck cranes have slow travelling capability (a few kilometers per hour) while suspending a load. Great care must be taken not to swing the load sideways from the direction of travel, as most anti-tipping stability then lies in the stiffness of the chassis suspension.

- Tower crane – It is usually fixed to the ground on a concrete. This crane often gives the best combination of height and lifting capacity and is used in the construction of tall buildings. The base of the crane is attached to a mast which gives the crane its height. Further the mast is attached to the slewing unit (gear and motor) that allows the crane to rotate. On top of the slewing unit there are three main parts which are: the long horizontal jib (working arm), shorter counter jib, and the operator’s cab. The long horizontal jib is the part of the crane that carries the load. The counter jib carries a counterweight, usually of concrete blocks, while the jib suspends the load to and from the center of the crane. The crane operator either sits in a cab at the top of the tower or controls the crane by radio remote control from the ground. In the first case the operator’s cab is most usually located at the top of the tower attached to the turntable, but can be mounted on the jib, or partway down the tower.

- Crawler crane – A crawler is a crane mounted on an undercarriage with a set of tracks which is also called crawlers. These crawlers provide stability and mobility to the crane. Crawler cranes have both advantages and disadvantages depending on their use. Their main advantage is that they can move around on site and perform each lift with little set up, since the crane is stable on its tracks with no outriggers. A crawler crane is also capable of traveling with a load. The main disadvantage is that these cranes are very heavy, and cannot easily be moved from one job site to another without significant expense. Typically a large crawler must be disassembled and moved by trucks, rail cars or ships to its next location.

- Rail road crane – This crane has flanged wheels for use on railroads. The simplest form is a crane mounted on a flat car. Most of these cranes are usually are purpose built and have high lifting capacities. The design differs according to the type of work but the basic configuration is similar in all cases. The configuration usually consists of a rotating crane body which is mounted on a sturdy chassis fitted with flanged wheels. The body supports the boom and provides all the lifting and operating mechanisms. On larger cranes, an operator’s cabin is usually provided. The chassis is fitted with buffing and coupling gear to allow the crane to be moved by a locomotive, although many are also self-propelled to allow limited movement about a work site.

- Floating crane – These are used mainly in the constructions of bridges and ports. They are also used for occasional loading and unloading of especially heavy or awkward loads on and off ships. Some floating cranes are mounted on a pontoon; others are specialized crane barges with a lifting capacity sometimes exceeding 9000 tons. These cranes are used to transport entire bridge sections. Floating cranes are also used to salvage sunken ships.

- Aerial crane – This crane is sometimes called sky crane. It is helicopter designed to lift large loads. Helicopter is able to travel to and lift in areas that are difficult to reach by conventional crane. Aerial crane is commonly used to lift units/loads onto shopping centers and high rise structures. This crane can lift anything within their lifting capacity. It also performs disaster relief after natural disasters for clean up, and during wild-fires it is able to carry huge buckets of water to extinguish fires.

- jib crane – It is a type of crane where a horizontal member (jib or boom), supporting a moveable hoist, is fixed to a wall or to a floor mounted pillar. Jib cranes are used in industrial premises and on vehicles. The jib may swing through an arc, to give additional lateral movement, or be fixed.

- Further to above cranes there are other types are cranes which are self erecting crane, bulk handling crane, loader crane, stacker crane, telescopic crane, deck crane, level luffing crane and hammer head crane etc.

Classification of cranes

Two cranes with the same rated capacity and span may differ in their average load intensity and/or expected loading cycles. There are different standards which classifies cranes based on the service class. The Crane Manufacturer Association of America (CMAA) classifies bridge cranes according to average load intensities and number of cycles. On the other hand, the classification all hoists by the International Organization for standardization (ISO), European Federation Standard (FEM) and Hoist manufacturer Institute (HMI) is according to more rigorous requirements, which include number of starts and maximum running time per hour. CMAA Crane classification and its comparison with other classification are given below. There are six different classifications of cranes by CMAA based on the duty cycle of crane.

- Class A (Standby or Infrequent service) – This crane is the lightest crane as far as duty cycle is concerned. This service class covers cranes where precise handlings of equipments at slow speed with long idle periods between lifts are required. Capacity loads may be handled for initial installation of equipment and for infrequent maintenance. Example of the use of Class A cranes are transformer station, power houses, turbine halls, motor rooms and public utilities etc.

- Class B (Light service) – This service class covers cranes where service requirements are light and speed is slow. Loads may vary from no load to occasional full rated loads with 2 to 5 lifts per hour, averaging 10 feet (3 meters) per lift. Examples of class B cranes include service buildings, light assembly operations, repair and maintenance shops and light ware housing etc.

- Class C (Moderate service) – Class C cranes are those cranes whose service requirements are deemed moderate. These cranes handle loads which average 50 percent of the rated capacity with 5 to 10 lifts per hour, averaging 15 feet (4.6 meters) with not over 50 percent of the lifts at rated capacity. Examples of class C cranes are the cranes usually used in paper mill machine rooms and machine shops etc.

- Class D (Heavy service) – In class D crane service, loads approaching 50 percent of the rated capacity is handled constantly during the work period. High speeds are desirable for this type of service with 10 to 20 lifts per hour averaging 15 feet (4.6 meters) with not more than 65 percent of the lifts at rated capacity. Typical examples of cranes with heavy service are steel warehouses, foundries, fabricating shops, heavy machine shops container yards and lumber mills etc. Cranes may be with standard duty buckets or magnets operations where heavy duty production is required.

- Class E (Severe service) – Cranes with class E service are capable of handling loads approaching the rated capacity throughout its life with 20 or more lifts per hour at or near the rated capacity. Application of canes with class E include magnet, bucket, magnet/bucket combination cranes or fertilizer plants, cement plants, scrap yards, lumber mills and container handling etc.

- Class F (Continuous severe service) – Cranes with class F service are to be capable of handling loads approaching rated capacity continuously under severe service conditions throughout its life. Typical examples of such cranes include custom designed specialty cranes essential for performing the critical work tasks affecting the total production facilities. This type of crane must provide the highest reliability with special attention to ease of maintenance features.

Dongqi Types of Cranes Offering

Related Products

![European Standard Double Girder Overhead Crane]() European Standard Double Girder Overhead Crane

European Standard Double Girder Overhead Crane![European Standard Double Girder Overhead Crane]() European Standard Double Girder Overhead Crane

European Standard Double Girder Overhead Crane![HD Electric Hoist Overhead Crane]() HD Electric Hoist Overhead Crane

HD Electric Hoist Overhead Crane![HD Electric Hoist Overhead Crane]() HD Electric Hoist Overhead Crane

HD Electric Hoist Overhead Crane