Power plant overhead crane is European double girder overhead crane which used in the main plant of the power plant, with low clearance, compact structure, security and firm use. It is usually installed in the main plant of the power plant, for generator set installation and maintenance, electrical equipment and other items lifting and handling.

During the construction of the power plant began installing generator unit, large generator unit need two bridge cranes of power plant to lift generator stator, generally exceed the rated lifting capacity of the cranes, each bridge of the bridge crane need to be reinforced, the two cranes with parallel control, and lift the generator stator at the same time for installation. The rest of the time, power plant crane do some maintenance, lifting and handling of some electrical equipment, with infrequent use, low working level, as A3.

Power plant crane traveling and hoisting mechanism should adopt frequency control system, PLC control system.

Crane, trolley and hoisting mechanism are all with safe and reliable braking systems, end travel limit device and buffer device. Anti-collision device is also provided between the cranes.

Power plant crane main hook and auxiliary hook can work simultaneously, and auxiliary hook should be coordinated work with the main hook for tipping or flipping the lifting object. Hook material of high quality carbon steel forging, and with heat treatment and non-destructive testing, metallurgical analysis, there is safety device to prevent rope falling off.

Wire rope length at minimum limit position, the rope also left enough safe laps of not less than three laps on the reel.

Power plant crane using centralized lubrication system, no oil leakage. Set with intercom communication system, thermal insulation control room, setting cold and warm air conditioning.

The power plant crane has its features, which are showned as following:

The power plant crane has the following safety measures, such as short circuit protection, ground protection, overcurrent protection, no-voltage protection, zero protection, rising limit protection, travel limit protection, emergency power-off protection, overload protection, etc.

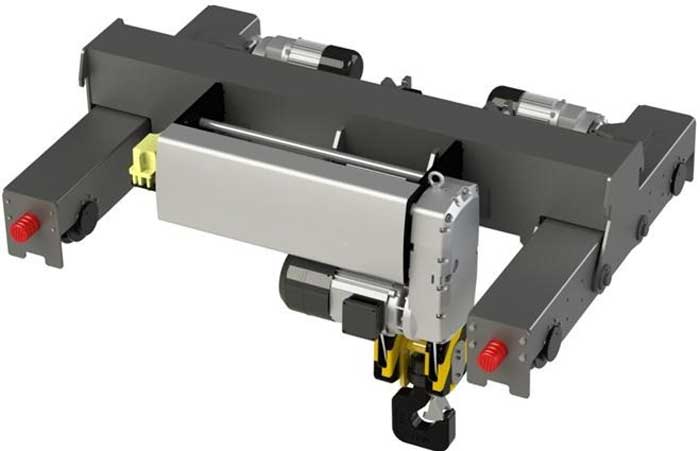

The power plant Overhead Crane mainly consists of bridge, crane traveling, trolley, driver’s cabin and electrical equipment.

Winch trolley power plant crane: trolley equipped with main and auxiliary hoisting mechanism, each using a separate set of transmission system. Main and auxiliary hoisting mechanism not only can independently complete lifting work, but also collaborative complete flipping device work.

electric hoist of the power plant crane: electric hoist trolley mechanical system mainly consists of ND electric hoist, frequency conversion deceleration traveling motor, driven wheels and other components.

The traveling mechanism of the power plant crane adopts three-in-one gear motor drive, with simple structure, easy maintenance. Its inverter system can provide smooth acceleration features and a variety of operating speeds, with smooth starting and braking, simple operation and accurate positioning.

Trolley frame, crane end beams and wheel assembly supporting surface adopt overall processing, to ensure that each wheel traveling as a united whole, with high precision of assembly, stable operation, and the wheel set can replaced very convenient, with advanced technology.

The power plant crane can be operated with the following ways:

Ground operation: press the button on the handle to control all crane mechanisms movements.

Remote control: control crane appropriate mechanism movements by industrial remote control.

Cabin Operation: linkage station of driver’s cabin to control operation of all mechanisms.

Driver’s cabin using new "space cabin" type, window use tempered glass of which thickness not less than 6mm. There is linkage control system, linkage table connected design with chairs, it is easy operation. All the cables linking use of heavy-duty air outlet, ensure tightness and joint strength. All the signs in cabin are clear.

To prevent corrosion during manufacturing process, pretreatment on the plate - sandblasting rust (rust grade Sa2.5 level, the degree of roughness EZ40-80 micron) and spraying epoxy zinc-rich primer pre-production, effective prevent corrosion during manufacturing process. After welding inspection, the whole power plant crane will be painted with two primer coat, one middle paint, two finishing coat, the total thickness of the paint film to reach 75 ~ 140μm.

Main and auxiliary lifting mechanism of the power plant crane are both equipped with overload limiter. When the load reaches 90% of rated load, issued of suggestive alarm signal; when lifting weight reaches more than 105% of rated load, it will automatically and immediately cut off the lifting power source, and issued prohibitory alarm signal. The power plant crane main equipped with analog tonnage display instrument.

According to crane mechanical safety rules, each exposed wounding dangerous rotating parts have to be set up with shields, and wire rope anti-pumping device. Shield in the form of detachable safety cover.

Platforms, walkways and ladders set up to facilitate the operator's maintenance and inspection. Ladders step, outdoor platform and walkway should be skip resistance, walkway, platform and ladder width not less than 500mm, walkway using tread plate.

The power plant crane installed with lifting height limiter and traveling stroke limiter, through electric control to achieve security protection for traveling stroke and locations.

Install cushioning device on crane to buffer crane operation braking kinetic inertia. While installed stop devices on the limit position of each crane operating mechanism to prevent the risk when crane runs exceeds the limit position.

Install rail sweep on crane to clean up debris on the rail, to prevent dangerous such as derailment caused by debris on the track. Rail sweep board is 10mm away from the track surface.

Set electrical interlock protection system in the crane railing door, cut off the supply power of which mechanism movement is dangerous for personnel.

Power plant crane electrical part installed with phase lack protection, wrong phase protection, low-voltage and overvoltage protection, short circuit protection, overcurrent protection, overload protection, ground fault protection and other electrical protection, sound and light alarm, to ensure crane operation under stable and safe conditions.

Contact us for more information on power plant crane.