Dongqi Crane has built a solid reputation for providing unparalleled service and support towards the repair, installation and maintenance of crane brakes.

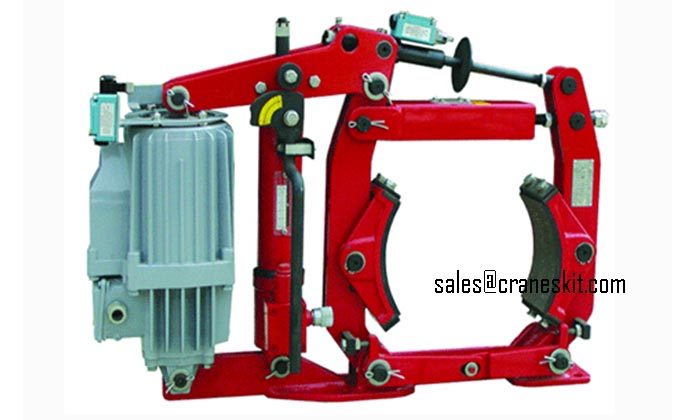

Whether you are operating an overhead, gantry, bridge, jib or everyday light duty workshop crane, you can rest assured our technicians will help you find the right solution for your application. Dongqi Crane supplies all types of friction brake parts, including disk brake, shoe brake and load brake parts and assemblies for all cranes.

It is critically important that replacement wear parts for all crane brakes are made of the correct friction material specified by your crane’s manufacturer.

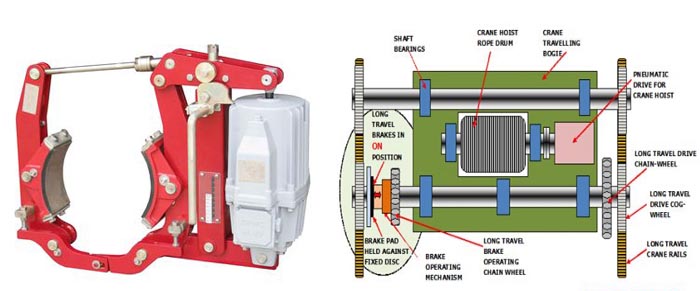

There are various types of brakes that can be successfully used for bridge and trolley motions. Traditionally, DC Magnetic Drum brakes have been the brake of choice, and AC and DC Thruster Drum brakes have become increasingly popular as they offer many features and benefits such as a sliding torque tube and lowering valve. Thruster or Magnetic Disc Brakes are also good options for bridge and trolley brakes as the calipers grip to a flat surface and thus achieve greater contact when interfacing with the disc which yields greater friction coefficient and ultimately better braking. Dual Caliper Disc brakes are an ideal blend of a disc and a drum brake as they provide even contact points with the disc which is similar to drum brakes while also gripping onto a flat surface as opposed to drum brakes which interface with a curved surface. Dual Caliper Disc Brakes provide a balanced load (zero overhung load) and ultimately present a safer option as there is no propensity for shaft twisting which can happen from the traditional disc brakes.

Hoist brakes are critical to the success and efficiency of many industrial operations and brakes are a vital component to the functionality and safety of the crane. On the high speed side of the crane, thruster or magnetic disc or drum brakes are used for service duty. Caliper Disc brakes are used for emergency duty and are on the low-speed side of the crane to prevent a load from falling in the event of s shaft breaking or transmission failure.

Hoist brakes are an essential safety feature of overhead cranes. Designed to hold a load when the hoist motor is not running, these brakes reduce the risk of falling loads that could result in injury and property damage.