Client Overview

A prominent construction materials company based in Casablanca, Morocco, approached DQCRANES with the need for a heavy-duty, weather-resistant single girder

gantry crane to support their outdoor yard operations. The client specializes in bulk concrete and steel material handling, requiring reliable and robust lifting solutions for their coastal facility.

Challenge

The customer needed a 2

5 ton gantry crane capable of withstanding Morocco's outdoor environmental conditions, including:

- High temperatures

- Coastal humidity

- Wind exposure

- Continuous daily operations

Key requirements included:

- Heavy Load Demands: Safely lifting and transporting 25-ton steel beams and concrete blocks.

- Space Constraints: A 16m span to cover their storage yard without obstructing workflows.

- Harsh Environment: Exposure to Casablanca’s humid, salty coastal air demanded corrosion-resistant equipment.

- Precision & Safety: Requiring precise control for delicate loads and compliance with safety standards.

The outdoor gantry crane also had to be delivered, installed, and operational within a strict 12-week period.

DQCRANES Solution

Custom Gantry Crane Design

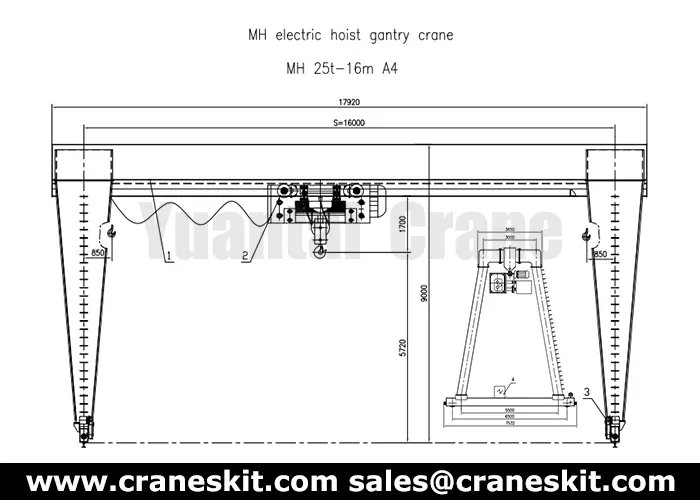

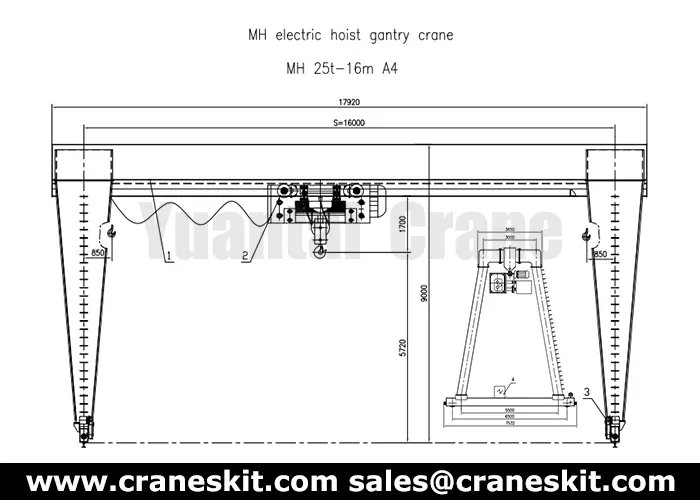

Custom Gantry Crane DesignDQCRANES engineered a

single girder gantry crane system using Q235B/Q345B steel, treated with marine-grade anti-corrosion coatings. The gantry crane specifications were designed with:

- Lifting Capacity: 25 tons

- Span: 16 meters

- Lifting Height: 5.72 meters

- Design: Outdoor gantry crane

- Control Options: Remote control & pendant control

- Corrosion Resistance: Marine-grade paint and IP-rated components

- Safety Features: Overload protection, limit switches, and emergency stop

- Rail Type: P38, Heavy-duty railmounted design

Hoist SelectionA MD series double speed electric

wire rope hoist from DQCRANES’ standard line was integrated with:

- High-performance motor

- Dual-speed control (0.8/8 m/min)

- Thermal overload protection

- Remote wireless control

The 25 ton gantry crane was designed to maximize yard space, improve material handling efficiency, and reduce manual labor.

Additional Features

- Storm locks to secure the crane during high winds

- Limit switches for safety

- Galvanized cable trays and protective conduit

- LED lighting system for night operations (Optional)

Export Details

- Country: Morocco

- Industry: Construction, Material Handling

- Shipping: 2×40’HQ containers via Tangier Port

- Installation: Remote support + On-site tech from local partner

- Delivery Time: 40 days production + 25 days shipping

Why Gantry Cranes for Bulk Concrete and Steel Handling?

Open Yard Flexibility (No Need for Building Support)Gantry cranes are self-supporting structures that run on ground rails, making them perfect for outdoor construction yards or precast plants. Unlike

overhead cranes, they don’t require building columns or a roof, which suits open storage of heavy concrete blocks, beams, steel coils, and rebar.

Wide Span & High ClearanceHeavy construction materials like precast concrete slabs or steel bundles are often long and bulky. Gantry cranes can be built with wide spans (10–40+ meters) and customized hook heights, making them suitable for:

- Loading/unloading flatbed trucks

- Stacking concrete products

- Maneuvering long steel rods or rebar

High Lifting CapacityGantry cranes support heavy-duty lifting, typically from 5 tons up to 100+ tons. This is ideal for:

- Concrete beams (which can weigh several tons each)

- Reinforced cages

- Large steel plates or rolled coils

Durable for Harsh EnvironmentsOutdoor yards are exposed to dust, heat, rain, and wind. Gantry cranes are designed with:

- IP-rated motors and control panels

- Weather-resistant coatings

- Wind limiters and storm locks

All these features make them reliable in rough outdoor conditions where concrete and steel are stored or fabricated.

Cost-Efficient for Large YardsFor wide, open construction zones or precast plants, gantry cranes are more economical than installing multiple mobile cranes or forklifts, especially when handling:

- Repetitive heavy loads

- Centralized lifting operations

- Linear production flows

Easy Integration with Concrete or Steel WorkflowThey integrate seamlessly into:

- Concrete casting beds

- Steel storage areas

- Loading zones near batching plants or fabrication units

Performance & Results

After installation and commissioning, the outdoor

gantry crane for sale to Morocco quickly became an integral part of the client's operations:

- 30% increase in handling speed

- Improved load precision with dual-speed hoist

- Reduced downtime and manual labor

- Safe and stable operations in outdoor conditions

The dual-speed hoist enabled operators to move loads slowly during positioning and quickly during long transfers — a key feature for working with heavy and fragile materials like precast concrete.

Client Testimonial

“DQCRANES delivered exactly what we needed: a strong, efficient gantry crane that fits our yard and workflow. Their team was responsive from design to delivery.”— Operations Manager, Construction Materials Supplier, Casablanca

types of cranes for Construction Yards in Morocco

Gantry Crane

- Best for: Outdoor yards, handling heavy materials (concrete beams, rebar, steel coils)

- Variants: Single girder, double girder, rail-mounted (RMG), rubber-tired (RTG)

- Key Benefits: No need for building support, wide span, heavy lifting, durable outdoors

- Use Cases: Precast concrete yards, steel storage areas, shipyard loading zones

Overhead Crane

- Best for: Indoor construction fabrication plants, precast concrete production

- Structure: Runs on elevated runway beams within a building

- Key Benefits: High precision, controlled environment, less weather exposure

- Use Cases: Concrete mold lifting, indoor steel structure assembly

jib crane

- Best for: Localized material handling in a small work area (like welding stations or casting pits)

- Types: Wall-mounted, floor-mounted, articulating

- Key Benefits: Flexible, compact, easy to install

- Use Cases: Moving small components, rebar cages, and construction tools

Monorail Crane

- Best for: Linear material movement along a fixed path (e.g., concrete panel transfers)

- Key Benefits: Simple design, efficient for repetitive processes

- Use Cases: Inside casting shops or limited-space areas

Portal Crane

- Best for: Port-adjacent construction yards or heavy industrial yards

- Structure: Similar to gantry crane but often taller with a slewing function

- Use Cases: Heavy equipment handling, coastal prefabrication yards

DQCRANES specializes in custom gantry cranes, overhead cranes,

electric hoists, and material handling solutions. With clients in over 100 countries, DQCRANES is known for its engineering excellence, on-time delivery, and customer-focused service.

Whether you're handling steel, concrete, or other bulk materials, DQCRANES delivers industrial lifting solutions built to last — even in the most demanding outdoor environments.

How to Custom Gantry Crane from DQCRANES?

Customizing a gantry crane from DQCRANES to tailor the crane’s specifications and features to your application. Here's a step-by-step guide to save your time and cost:

Define Your Requirements

- Load Capacity: Determine the maximum weight the crane must lift.

- Span & Height: Measure the workspace (distance between legs and lifting height).

- Application: Indoor/outdoor use, environmental conditions (e.g., corrosion, temperature, hazardous areas).

- Mobility: Rail-mounted, fixed, or mobile (wheeled/rubber-tyred) design.

- Control System: Pendant, radio remote, or automated controls (e.g., PLC integration).

- Power Supply: Electric (voltage requirements), hydraulic, or hybrid systems.

- Safety Features: Overload protection, emergency stops, anti-collision systems, or explosion-proofing.

Additional Features (Optional)You can customize:

- Hoist type (wire rope or chain hoist, hoist trolley or winch trolley)

- Anti-sway systems, inverter controls, and automation

- Color, Logos, etc

Contact us today, you can collaborate effectively with DQCRANES to create a gantry crane optimized for your operations.