DQCRANES designed and supplied a 2 ton KBK single girder

suspension crane for a truck assembly shop in South Africa. Our innovative KBK crane designs and unique features provide a reliable solution for clients' assembly lines.

Customer Background

Our esteemed client is a leading truck manufacturer in South Africa and their assembly shop was in desperate need of an efficient and reliable lifting solution. Recognizing the importance of optimizing manufacturing processes, they sought a solution that would increase productivity while maintaining high safety standards.

Customer Requirements

The customer's main requirement was a lifting crane system that could be seamlessly integrated into their existing assembly line. They emphasize the need for flexibility, ease of movement, and precise load handling capabilities. Additionally, they wanted a solution that maximized floor space and minimized any potential obstacles to workflow.

Our KBK Crane Design Solutions

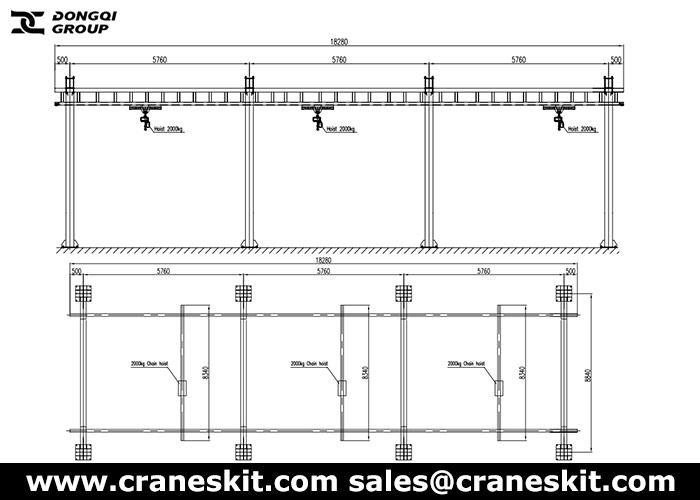

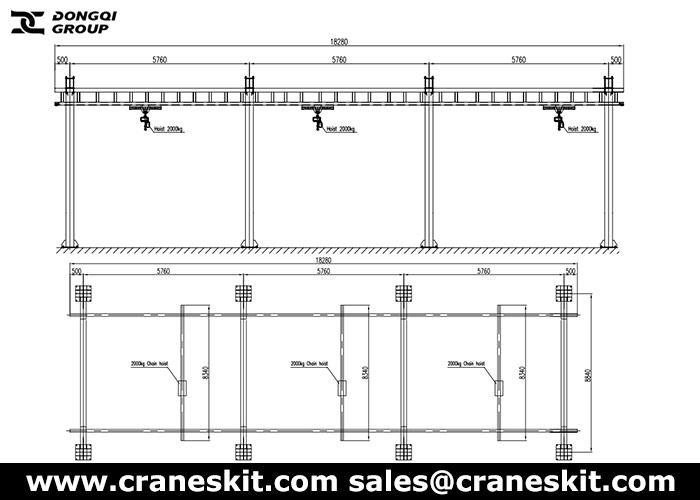

After fully assessing the customer's needs, our team of experts recommended the installation of a 2 ton KBK suspension crane. This innovative

workstation crane system will provide the necessary flexibility and efficiency for truck assembly operations.

- Capacity: 2 tons

- Span: 8.84 meters

- Lifting height: 4 meters

- Track length: 18.280 meters

- Girder qty: 3

- Lifting speed: 6.8 m/min

- Trolley speed: 20m/min

- Power supply: 380V/50Hz/3 Phase

- Soft start and stop

- Emergency stop

- Overload protection

The crane is also equipped with a variety of safety features, including:

- Load limiter

- Brake monitoring system

- Anti-collision system

- Emergency stop rope

- Pendant control

KBK Suspension Crane Design Features

- Lightweight and compact: KBK crane adopts a lightweight design of aluminum profiles, which reduces the load of the building structure while maximizing the lifting capacity. Its compact size enhances maneuverability in confined spaces, ensuring unimpeded workflow.

- Modular and customizable: The KBK suspension crane system adopts a modular design and is highly adaptable to various assembly line layouts. Custom features, such as different hook heights and spans, can be seamlessly integrated with existing equipment.

- Smooth and precise operation: KBK cranes adopt advanced control systems to ensure smooth and precise load handling. This increases productivity by minimizing downtime and reducing the risk of load damage during transport.

- Easy to maintain: KBK light crane systems are designed for easy maintenance, minimizing downtime, and optimizing overall efficiency. This feature ensures that the assembly line remains running for longer periods of time, maximizing productivity.

Why Choose Kbk Cranes For Assembly Lines?

- Enhanced Ergonomics: KBK light cranes are designed with ergonomics in mind. Operators can easily maneuver heavy objects, reducing the risk of workplace injuries. Precise control of the crane enables precise positioning, further enhancing ergonomics on the assembly line.

- Improve productivity: The lightweight and compact design of KBK cranes speed up the assembly process and significantly shorten production time. Operators can easily move loads to individual workstations, eliminating bottlenecks and streamlining workflow.

- Space optimization: KBK cranes are compact in size, allowing for optimal space utilization. This allows efficient planning and utilization of floor space, ensuring smooth workflow and preventing unnecessary obstacles.

Here are some specific examples of how KBK suspension cranes are used on assembly lines:

- Automotive assembly: KBK cranes are used in automotive assembly lines to lift and move car bodies, engines, and other components.

- Electronics assembly: KBK cranes are used in electronics assembly lines to lift and move circuit boards, components, and other materials.

- Food and beverage processing: KBK cranes are used in food and beverage processing lines to lift and move ingredients, packaging materials, and other items.

- Pharmaceutical manufacturing: KBK cranes are used in pharmaceutical manufacturing lines to lift and move ingredients, packaging materials, and finished products.

All in all, the KBK cranes can provide the ideal solution for different assembly requirements. With their ergonomic features and space optimization capabilities, KBK cranes are indeed the first choice for assembly lines in various industries.

Contact DQCRANES to get the custom KBK crane system for your needs.

KBK Suspension Crane Types

KBK single girder suspension cranes:

- The KBK-LD type flexible modular single girder suspension crane is made up of standard linear track and other standard components.

- The trolley traveling part at both ends of the main beam can be run on two tracks perpendicular to the main beam's direction, the single beam can be used with any type of fixed chain hoist, and the special KBK driving device can drive the hoist to run along the main beam's direction.

- This type of product is used for material transportation by plane and can be used in a workshop or warehouse.

- Because of its unique flexibility and degree of freedom, the flexible modular single-beam suspension crane can be inclined to run on the track, walk on the track with the variable span, and run on two concentric circular curved tracks, which other types of lifting products cannot.

- The flexible composite single-beam suspension crane has a maximum span of 10 meters and a maximum lifting capacity of 2000kg.

KBK double girder suspension cranes:

- KBK-LS type flexible modular double girder suspension crane comprises standard linear track and other auxiliary standard parts.

- The trolley traveling part at both ends of the main beam can be run on two tracks perpendicular to the direction of the main beam, the single beam can be used with each type of fixed chain hoist, and the special KBK driving device can drive the hoist to run along the direction of the main beam.

- The flexible modular double girder suspension crane is used to lift heavy materials with a large span due to the use of double-rail parallel composite beam to increase the load-bearing capacity of the main beam.

- KBK Double-girder suspension cranes feature a low deadweight and favorable structural dimensions.

- Double-girder suspension cranes can even be installed in buildings of light steel construction.

- KBK classic double-girder cranes can also operate on several runways, thus providing large spans to cover extensive storage and production areas.

- The KBK cranes can be easily moved by hand. However, electric friction wheel travel drives from the KBK crane construction kit are recommended for spans greater than 6 meters and load capacities exceeding 3000 kg.

Get KBK Crane Price!

As a reputable KBK crane manufacturer, DQCRANES will be able to help you choose the right crane for your needs and provide you with a quote based on your specific requirements.

Contact us for a free KBK crane price now!