To support the setup of a new pump repair and maintenance workshop in Cyprus, DQCRANES successfully designed, manufactured, and exported a 2 ton

floor mounted jib crane, offering a highly efficient and space-saving lifting solution for the client.

Client Background

The client, a mechanical contractor specializing in pump installation and overhaul, required a reliable and flexible material handling solution to lift and maneuver heavy pump components inside their newly established workshop.

Project Overview

- Location: Cyprus

- Client: Local mechanical and pump maintenance contractor

- Application: Lifting and positioning heavy pump components (such as motors, impellers, and housings) during maintenance and assembly operations

- Supplied Equipment: 2 ton floor mounted crane with electric chain hoist

Customer Challenges

The customer was establishing a new pump servicing workshop with a need to:

Efficiently lift and handle pump equipment weighing up to 2 tons

Optimize limited floor space

Reduce labor intensity and improve operational safety

Ensure full coverage within the workshop working area

Custom Jib Crane Solution - DQCRANES

DQCRANES provided a pillar-mounted jib crane customized to the workshop layout. With 360° rotation, the 2 ton jib crane can service multiple workstations. The electric chain hoist with dual speed offers smooth lifting, precise control, and built-in overload protection for added safety.

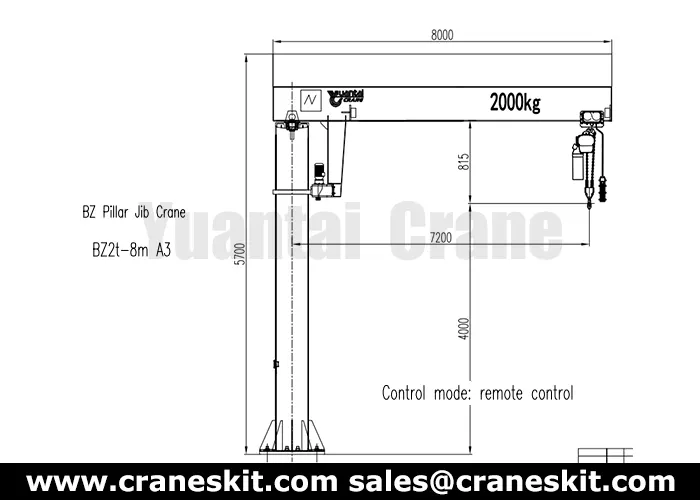

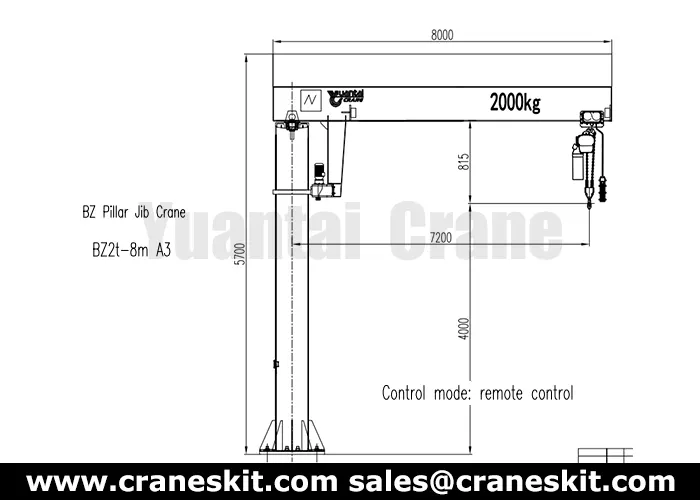

Technical Specifications

- Lifting Capacity: 2 tons

- Valid Radius: 7.2 meters (Arm Length 8 meters)

- Lifting Height: 4 meters

- Rotation Angle: 360° electrical rotation 0.4 r/min

- Hoisting Speed: 3.3/1.1 m/min

- Power Supply: 400V, 50Hz, 3-phase

- Mounting Type: Freestanding, floor-mounted

- Hoist Type: Electric chain hoist, dual speed

Design FeaturesTo ensure long-term reliability and ease of maintenance, the

jib crane for sale in Cyprus was fabricated using high-quality structural steel, featuring anti-corrosion surface treatment and modular parts for rapid installation.

- Full 360-degree coverage with minimal footprint

- Heavy-duty performance with compact structure

- Easy installation with anchor bolts and base plate

- Energy-efficient electric hoist with low noise

Benefits of a Floor Mounted Jib Crane in Cyprus

A floor mount jib crane is one of the most efficient and cost-effective lifting solutions for industrial and commercial workshops across Cyprus. Whether used in pump maintenance, mechanical assembly, or warehouse logistics, it offers significant advantages in terms of performance, flexibility, and safety.

Independent and Space-Efficient Operation

- Unlike wall-mounted or ceiling-suspended cranes, a floor mounted crane is completely independent of building structures, making it ideal for workshops without existing support beams. It utilizes minimal floor space while maximizing vertical and radial reach.

360-Degree Rotation for Full Coverage

- Many floor-mounted jib hoist cranes offer up to 360° manual or motorized rotation, allowing workers to lift, swing, and position heavy loads anywhere within the crane’s radius — perfect for multi-station work zones in pump or mechanical workshops.

High Lifting Capacity for Heavy Loads

- These free standing cranes can be engineered for capacities ranging from 500 kg to 15 tons or more, making them suitable for lifting heavy machinery components, such as motors, pumps, gearboxes, and structural parts commonly used in Cyprus-based industries.

Improved Safety and Reduced Labor Effort

Improved Safety and Reduced Labor Effort

- By automating the lifting process and reducing the need for manual handling, floor jib cranes significantly lower workplace injury risks and increase productivity, a key factor for small to mid-sized businesses in Cyprus looking to scale efficiently.

Customizable for Various Applications

- Whether you're setting up a new pump workshop in Nicosia, a mechanical plant in Limassol, or a warehouse in Larnaca, DQCRANES offers customized floor mounted jib cranes with configurable arm length, height, hoist type, and rotation limits to fit your unique operational layout.

Customer Feedback

“

DQCRANES not only solved the space limitation problem in our workshop, but its remote debugging support also avoided the cost of international travel. From Google search to crane installation, the whole process is seamless.”

— Workshop Supervisor, Cyprus

Ready to Upgrade Your Workshop?

Whether you're setting up a new facility or upgrading existing operations, DQCRANES offers custom jib cranes,

gantry cranes,

overhead cranes, and hoist systems tailored to your industry.

Contact us today to discuss your project.

How to Install a Floor Mounted Jib Crane?

Here’s a step-by-step guide to help you understand the process and prepare for a successful jib crane installation.

Step 1: Prepare the Foundation

Step 1: Prepare the FoundationA solid concrete foundation is crucial to support the weight and dynamic forces of the jib crane.

Foundation Requirements:

Concrete thickness: Typically 300–500 mm (may vary by crane capacity)

Concrete strength: Minimum C30 or equivalent

Reinforced with rebar: For added structural integrity

Foundation area: Based on crane load and rotation angle (provided by DQCRANES in the foundation drawing)

Step 2: Anchor Bolt InstallationBefore placing the crane:

Insert anchor bolts into the wet concrete or use chemical anchors if drilling after curing.

Ensure precise bolt alignment to match the crane base plate holes.

Let the concrete cure fully (usually 7–14 days) before proceeding.

Step 3: Mount the Crane Base ColumnOnce the foundation is ready:

Position the crane’s base plate over the anchor bolts.

Use a spirit level to ensure vertical alignment.

Tighten nuts and washers securely using a torque wrench.

Important: Uneven base installation can lead to crane instability or operational failure.Step 4: Assemble the Jib Arm and HoistAttach the horizontal jib arm to the top of the vertical column.

Mount the electric chain hoist on the arm’s trolley.

Secure all connections according to the assembly manual.

Adjust end stops to prevent the trolley from sliding off the beam.

Step 5: Electrical and Safety ConnectionsConnect the electric hoist to a 3-phase power supply (or single-phase, depending on your setup).

Install a limit switch, emergency stop, and control pendant.

Check grounding and electrical safety compliance.

Step 6: Load Testing and CommissioningBefore full operation:

Perform a no-load test to ensure smooth rotation and lifting.

Conduct a load test (usually 125% of rated capacity) as per ISO or EN lifting standards.

Inspect all bolts, electricals, and safety mechanisms.

DQCRANES can provide load test certification and video support upon request.Optional: DQCRANES Installation SupportIf you're unsure, DQCRANES offers remote or on-site support in Europe, including Cyprus:

- Foundation drawing

- Installation manual

- Video guidance

- Spare parts and technical support

Why Choose DQCRANES?

✅ Customized lifting equipment based on workshop needs

✅ Fast international delivery and technical support

✅ Proven experience in mechanical and industrial sectors

✅ One-stop service from design to installation assistance