The lever hoist is a classification of manual hoist.Lever hoist is a simple to use, easy to carry manual lifting tool. Lever hoist can be promoted, traction, drop, calibration and other operations. From the general weight of not more than 50T. The lever hoist is mainly divided into hand chain lever hoist and wire rope pulling hoist.

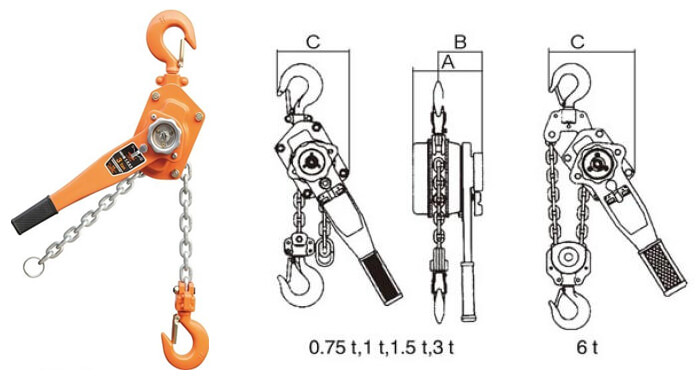

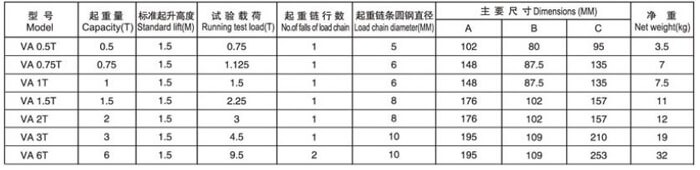

VA type lever hoist rated lifting capacity is 750kg, 1500kg, 3000kg, 6000kg and 9000kg.The VA type chain lever block is widely used in factories, mines, construction areas, docks and transport conditions. It is the ideal tool for equipment installation, object lifting, object fixing, banding and towing, especially suitable for towing of random angle and working in scanty place, open air and place with no power supply.

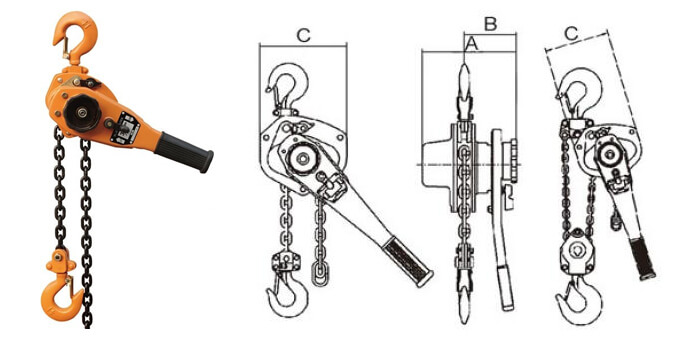

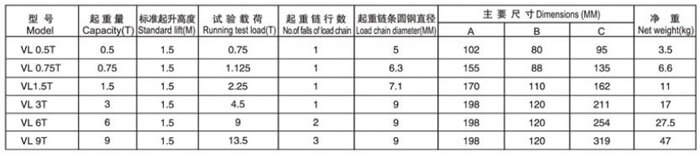

VL series lever hoist is a kind of portable and versatile hand–operated loading and pulling appliance, which is capable of being applied in electricity, mines, ship buildings, construction sites, transports, post and telecommunication for installing equipment, lifting goods, pulling mechanical parts, bulk strapping and fastening, tightening fitting of wires, assembling and welding etc. It has exceptional advantages particularly for pulling in every limited narrow places, in the upper air high above the ground and at any angles.

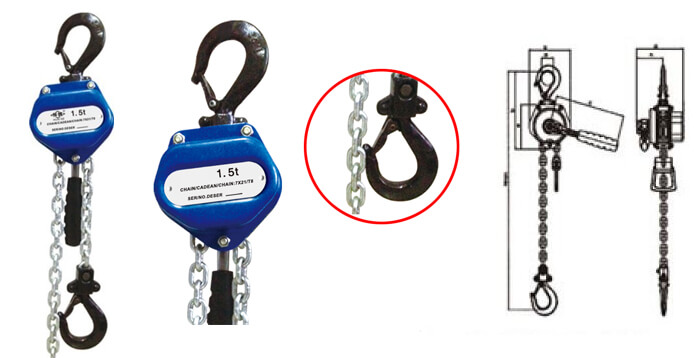

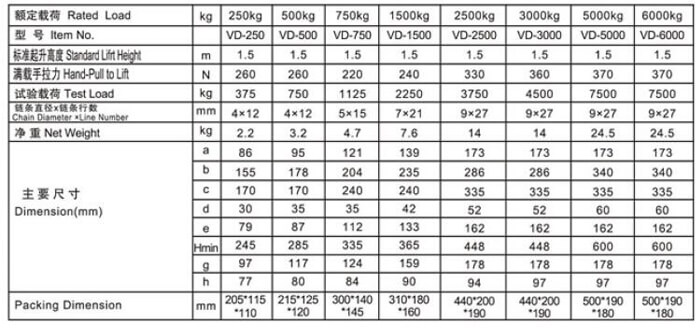

Before using the VD type lever hoist, familiarize yourself with main parts is very important. Always check the hoist for proper operation before using and not using the malfunctioning hoist. Read and understand this manual will help to reduce the risk of injury.

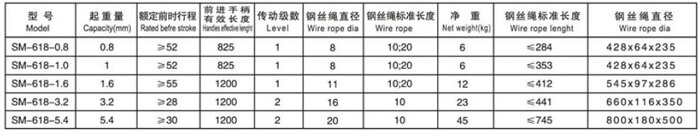

Wire rope aluminum alloy lever hoist applies to narrow restricted space. For field working, aerial working, trenches, Sham Tseng iob and non-electromechanical energy supply lifting operation has superiority.

Wire rope lever hoist, also known as wire rope traction machine, wire rope pull machine, is a new, efficient, safe and durable lifting machinery products, with lifting, traction, tension three functions, the whole structure of a reasonable design, high safety factor, long life, especially for the field without power source status under.

Wire rope aluminum alloy lever hoist is leveraged by hand, with the aid of the principle of leverage to match the load to match the linear traction, the role of rotation on the movement of a clamp body to drive the load operation.

If lever hoist equipped the special device, not only can be used for non-linear traction operation, and can easily choose the appropriate operating position, or smaller tonnage of equipment to expand its load capacity, for larger tonnage load can be used several parallel operation.