What’s the Basics of Crane Safety?

09 Aug, 2017

Let us imagine that if you are a rich-experience crane operator, will you have the below thoughts sometimes?

- You've carefully thought out all the angles.

- You've done it a thousand times.

- It comes naturally to you.

- You know what you're doing, it is what you have been trained to do your whole life.

- Nothing could possibly go wrong, right?

All these ideas are a hurt at work and in order to have a good working condition today we will explain some basics of crane safety.

Hope these can help you and protect yourselves from the dangerous.

Basics of Crane Safety

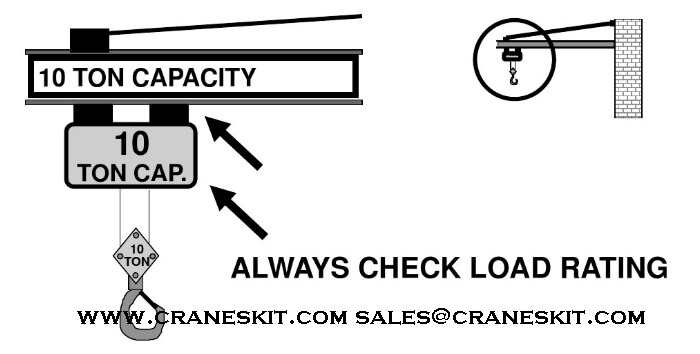

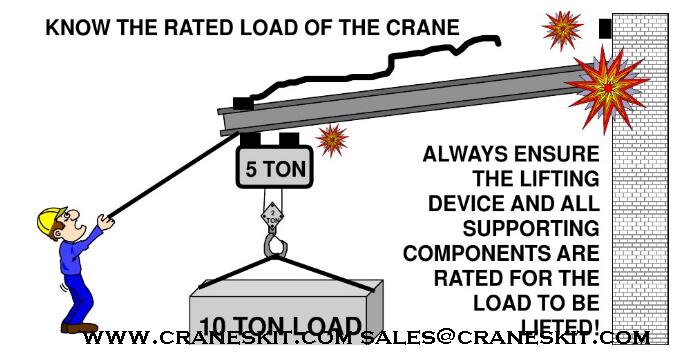

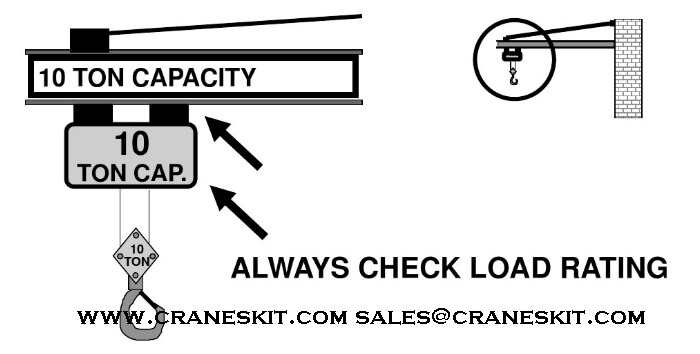

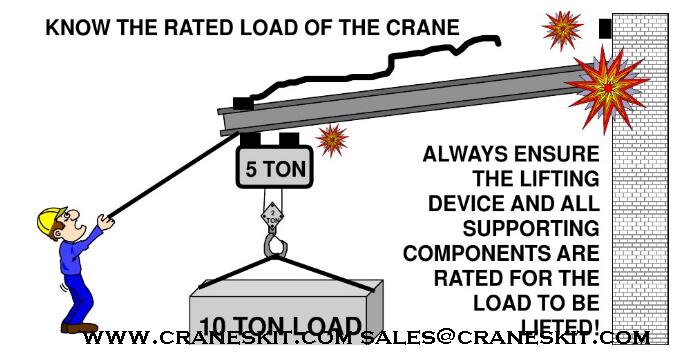

- Know the rated load of the crane

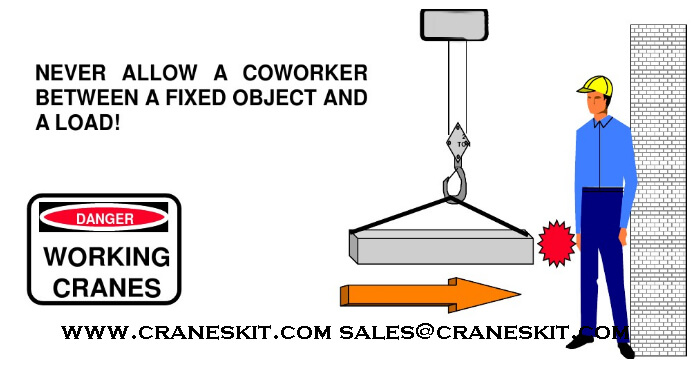

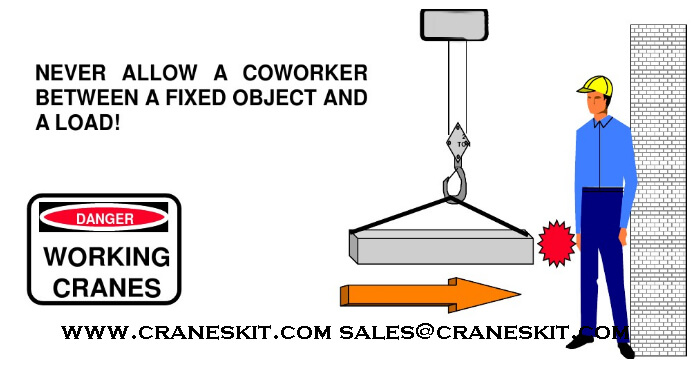

- Never allow a coworker between a fixed object and a load

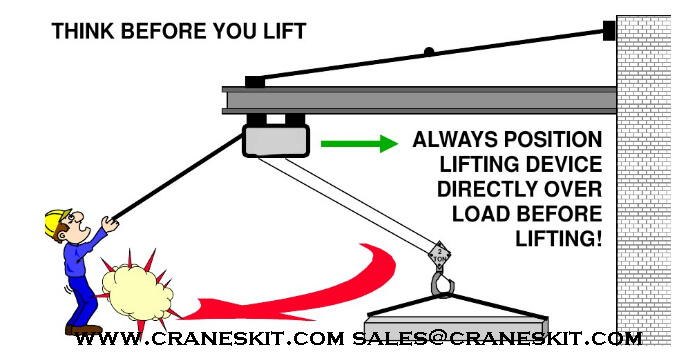

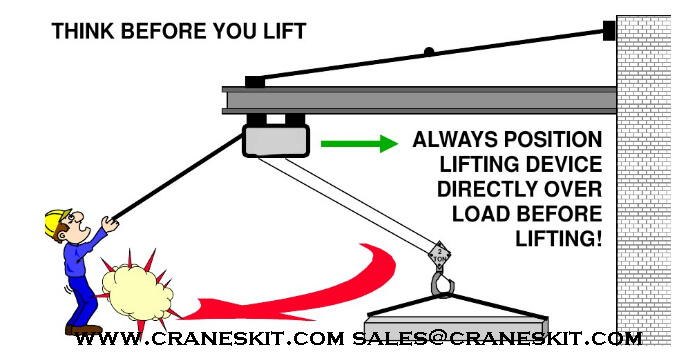

- Think before you lift

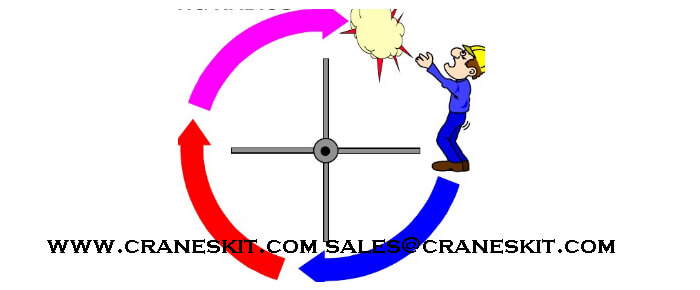

- Know your safe working radius.Always ensure that you know the safe travel radius of the crane. Contact with electrical sources or other hazards can result in catastrophic consequences.

- Dissipate all hazardous energy.Always ensure energy sources are dissipated before initiating any maintenance activity.

Lifting operations are inherently dangerous. Even when proper training is conducted, equipment is properly maintained, employees conduct themselves in a safe manner, and other facets of the safety program are conscientiously attended to, accidents can still occur.

The reason is that crane operations are primarily dependent on mechanical devices. These devices can and do fail. When this happens during a lifting event the results can be catastrophic. You are the only controlling influence that can minimize the hazard. Your life literally is in your own hands!

Safe practices for operators:

- Test all hoist controls and brakes at the beginning of each shift.

- Never attempt to operate a crane or hoist that is suspected to be unsafe.

- Always test brakes by a short lift to ensure control.

- Move loads only after being signaled by the designated, qualified signaler.

- Never carry loads over workers.

- Never carry loads past workers (they must yield right of way).

- Signalers must keep line-of-sight with the operator.

- Never allow riders on loads or hooks.

- Never allow unauthorized persons to operate cranes.

- Always lockout before maintenance or repairing cranes.

- Frequently inspect cranes exposed to adverse conditions.

- Always position the hook directly over the load before lifting the load off of the floor.

- Document and maintain inspection records

- Check warning devices and signals before use.

- Signalers must watch the load.

- Operators must watch the signalers.

- Know your travel path in advance of the lift!

- Know where you're going to set the load down!

- Will the new location support the weight?

Safe Practices for Signalers

- Only one person is designated signaler.

- Maintain line-of-sight with the operator.

- Ensure the operator acknowledges every signal.

- Stop the operation if comprehension is lost.

- Operators must watch the signalers.

- Plan in advance where the load is going!

- Know the new location will support the weight.

Leaving or Parking Hoists or Cranes

- Raise all hooks to - but not through - limit switches.

- Place all controls in the "off" position.

- Place main power switch in the "off" position.

- Make a visual check for any dangerous condition.

- Report any defects immediately.

- Tag out defective equipment immediately.

- Report all cranes that are not in operation immediately.

- Follow the manufacturer's recommendations.

Keeping safe during the work is not only responsible for yourself but also for your family. No matter how much experience you have, always remember that safe is in the first place.Enjoy your work and enjoy life!

Related Products

![Adjustable Gantry Crane]() Adjustable Gantry Crane

Adjustable Gantry Crane![Mobile Gantry Crane]() Mobile Gantry Crane

Mobile Gantry Crane![Truss Gantry Crane]() Truss Gantry Crane

Truss Gantry Crane![Rail Mounted Container Gantry Crane]() Rail Mounted Container Gantry Crane

Rail Mounted Container Gantry Crane