Crane installation in steel coil plant for our Bangladesh customer. 10 ton Double Girder overhead crane provided for our Bangladesh customer. Let’s show you the crane installation process of 10 ton Double Girder Overhead Crane in Bangladesh.

10 Ton Double Girder Overhead Crane in Bangladesh

Greetings to inform you that we have finished the 10 tons double girder overhead crane commission for one of our client in the Chittagong, Bangladesh.

Our client is in the steel coil area. From the 2013 years on, they bought 3 sets double girder overhead cranes from us and this is the fourth overhead crane. Its plant notably is the only European plant of its kind in the country, supplied by SMS DEMAG Germany, a world leader in this sector. The Complex which is built on a 10 acre site, houses pickling line, 6 Hi CVC cold rolling Mill Slitting and rewinding line with an annual capacity of 250000 MT. Commission in 18 months under direct supervision and technical assistance of SMS DEMAG Germany, the result is a continuous and efficient supply of flawless quality product unrivalled by any other in the industry, thus enabling us to be the most reliable supplier of cold rolled sheet in the region.

When the first day we arrived the Chittagong, Bangladesh, We discussed the installation plan with them as below:

Linked the main girder-----Fixed the maintenance platform---Fix one piece end carriages---Fix the two main girder----Fix the second end carriages-----Fixed the end carriages & main girder well----Fix the lifting trolley----Connect the electrics----load testing/commission

Our engineer guided the workers to link the main girder by high strength bolts firstly. After then, welded it again. As there is the trolley rail mount on the main girder, after the connection, we have to clear the rail also.

Main Girder Weld

As for our general design, there will be one side maintenance platform on the main girder. So after linked the main girder, our engineer asked the workers to fix the maintenance platform.

Fix Crane Maintenance Platform

Then we asked our client to rent one mobile crane. With the mobile crane help, we lifted up and fixed one side end carriage firstly. Then we dispatched two person to the upside with safety belts and asked them to hold the end carriages by wire rope.

10 Ton crane end carriage Installation

After one side end carriages fixed well, our engineer asked to lift the two main girders up one by one. Connect the end carriages and main girder by high strength bolts.

10 Ton Crane Main Girder Installation

After then, our engineer asked to link the second end carriage. Fix the other side end carriage and main girders by high strength again.

Then our engineer asked the mobile crane to lift the lifting trolley up. Meanwhile, he asked two workers to fix the trolley by wire rope to assort the lifting trolley loading.

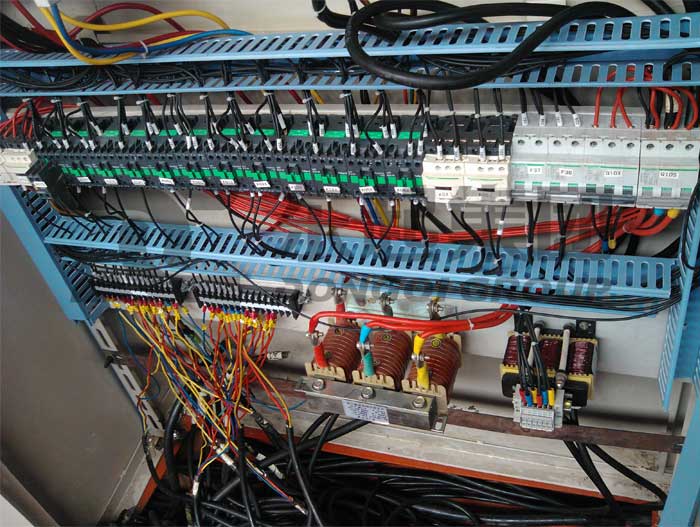

After all the mechanical job fixed well, our engineer connected the electrics with the help of our electrics drawings.

Crane Electrics Connection

After then, our engineer asked to connect the power and we start the load testing and commissioning.

As per our design standard, our load testing is divided into two parts:

Static testing, this is the 1.25 times testing. We asked our client to prepare the 12.5 tons cargo and lift it 3 meters up from the ground.

Dynamic testing, this is the 1.1 times testing; We asked our client to prepare the 11 tons cargo; We asked our client to lift the cargo 5 meters up from the ground; After then, our engineer test the trolley cross traveling and crane long traveling also.

10 Ton Crane Load Testing

Till then, all the cranes installations and commissioning has been finished.

As you know, Dongqi Group can provide you not only cranes but also crane installation service. Double girder overhead crane installation in Bangladesh was required by our customer. Our Bangladesh customer believes that our engineer is more professional and efficient and it’s the truth.If you have any need about cranes and hoists, please feel free to contact us.